The construction industry is undergoing a significant transformation, driven by innovative technologies and materials that enhance efficiency and sustainability. At the forefront of this evolution is the Neodymium Precast Concrete Magnet, a tool that has gained considerable traction in modern construction practices. According to a recent report by the Global Construction Materials Market, the use of advanced materials, including precast concrete solutions, is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2022 to 2030.

The 138th Canton Fair in 2025 serves as a pivotal platform to showcase these advancements, particularly the adoption of Neodymium Precast Concrete Magnets, which improve assembly speed and structural integrity. This innovative approach not only meets the rising demand for efficient construction methods but also aligns with global sustainability goals, making it a topic of great interest for industry professionals attending the fair. As stakeholders look to revolutionize their construction processes, the integration of these magnets represents a promising step towards a more efficient and sustainable future.

The 138th Canton Fair in 2025 serves as a pivotal platform to showcase these advancements, particularly the adoption of Neodymium Precast Concrete Magnets, which improve assembly speed and structural integrity. This innovative approach not only meets the rising demand for efficient construction methods but also aligns with global sustainability goals, making it a topic of great interest for industry professionals attending the fair. As stakeholders look to revolutionize their construction processes, the integration of these magnets represents a promising step towards a more efficient and sustainable future.

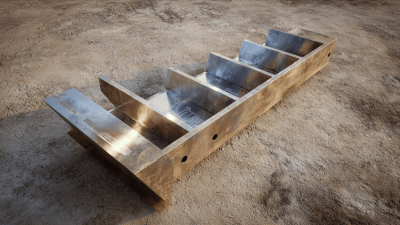

Neodymium magnets are making significant strides in the precast concrete industry, especially notable at the upcoming 138th Canton Fair in 2025. These powerful magnets offer innovative solutions for enhancing the efficiency and precision of precast concrete production. By utilizing neodymium magnets, manufacturers can streamline the assembly process, reduce material handling time, and improve the overall quality of concrete components. The ability to easily manipulate and secure forms during the casting process not only accelerates production but also minimizes the risk of defects.

Moreover, the innovative applications of neodymium magnets extend beyond mere production efficiency. They enable the creation of more complex designs and structures by allowing for modular construction methods. This flexibility opens up new possibilities for architects and engineers to explore unique architectural concepts while maintaining structural integrity. As the construction industry continues to evolve, the integration of neodymium magnets is set to redefine the manufacturing landscape, making it a focal point of discussion at the Canton Fair. The potential for enhanced sustainability and reduced labor costs further solidifies the role of these magnets in the future of construction.

As the construction industry continues to evolve, the demand for innovative materials is on the rise. Neodymium-based construction materials are emerging as key players in this transformation, particularly in the precast concrete sector. With their unique magnetic properties, neodymium magnets are revolutionizing the way construction is approached, offering solutions that enhance efficiency and reduce costs. The 138th Canton Fair in 2025 is poised to showcase these advancements, highlighting the potential for neodymium precast concrete magnets to reshape traditional construction methodologies.

Market growth for neodymium-based construction materials is expected to accelerate significantly by 2025. As sustainability becomes a critical focus in building projects, the ability of these materials to facilitate quicker assembly and disassembly is attracting attention from developers and builders alike. Incorporating neodymium magnets in precast concrete designs not only optimizes workflow but also contributes to environmentally friendly practices, reducing waste and resource consumption. The Canton Fair will be an essential platform for industry stakeholders to explore these trends, establish partnerships, and capitalize on the growing interest in innovative construction solutions.

| Market Segment | 2023 Market Size (Million USD) | Projected 2025 Market Size (Million USD) | CAGR (%) | Key Drivers |

|---|---|---|---|---|

| Residential Construction | 1500 | 2500 | 28.0% | Increased urbanization, Eco-friendly trends |

| Commercial Construction | 2000 | 3200 | 26.0% | Investment in smart buildings, Sustainability |

| Infrastructure Projects | 2500 | 4000 | 22.0% | Government spending, Public-private partnerships |

| Industrial Construction | 1800 | 2800 | 30.0% | Manufacturing growth, Urban development |

The adoption of neodymium in precast concrete magnets marks a significant advancement in sustainable construction practices. By integrating neodymium—a rare earth element known for its remarkable magnetic properties—into construction processes, builders can reduce reliance on traditional methods that often involve excessive energy consumption and resource depletion. This innovative approach not only enhances efficiency in construction but also minimizes environmental impact, making sustainability a core focus of modern building techniques.

Moreover, utilizing neodymium in construction aligns with global efforts to combat climate change and promote eco-friendly materials. The lightweight nature of neodymium magnets facilitates easier handling and installation, leading to reduced transportation costs and lower carbon footprints. In addition, the durability and strength of neodymium-infused precast concrete ensure longer-lasting structures, thereby decreasing the frequency of repairs and the associated waste.

As the industry continues to evolve, the environmental benefits of neodymium will play a crucial role in the transition toward greener construction practices, showcasing a commitment to sustainable development at events like the the 138th Canton Fair in 2025.

The construction industry is experiencing a significant transformation with the integration of neodymium precast concrete solutions, showcased at the 138th Canton Fair 2025. Case studies presented at the event highlight how various companies have successfully adopted these innovative techniques, leading to enhanced efficiency and cost-effectiveness. One notable example comes from a construction firm that utilized neodymium magnets in their precast panels, allowing for quick, secure assembly on-site. This method not only reduced labor time but also minimized the risk of structural misalignment, showcasing the practical advantages of this technology.

Another inspiring case study involved a sustainable housing project that employed neodymium precast concrete elements. By leveraging the strength and versatility of these materials, the project achieved remarkable energy efficiency and durability, meeting modern architectural standards. The use of neodymium magnets facilitated seamless connections between different precast components, resulting in a faster construction timeline and a notable decrease in material waste. These implementations serve as a testament to the transformative potential of neodymium precast concrete solutions in shaping the future of construction.

This chart illustrates the projected market growth for neodymium precast concrete solutions from 2021 to 2025. The consistent increase demonstrates the rising interest and adoption of innovative concrete technologies within the construction industry.

The future of the construction industry is poised for a transformative revolution, driven by advancements in magnetic technology. As we explore the integration of AI, quantum computing, and nuclear energy, we see a landscape ripe with opportunities. Notably, the utilization of neodymium magnets in precast concrete is leading to enhanced structural integrity and sustainability. This innovation not only improves load-bearing capabilities but also streamlines assembly processes on-site, paving the way for a smarter, more efficient construction paradigm.

Tips for industry stakeholders include investing in research on composite materials and their magnetic properties, as these advancements can significantly reduce costs while enhancing performance. Additionally, embracing machine learning can drive the development of bespoke construction solutions tailored to specific project needs. Engaging with emerging technologies will undoubtedly empower companies to stay competitive and innovative in an ever-evolving market.

In the realm of magnetic technology, recent strides in magnetic aptasensors signal a shift towards more efficient biosensors. The construction sector can benefit from these advances by exploring applications that monitor structural health, thereby increasing safety standards and operational longevity. As the industry continues to evolve, harnessing these technological innovations will be essential for realizing a sustainable future in construction.