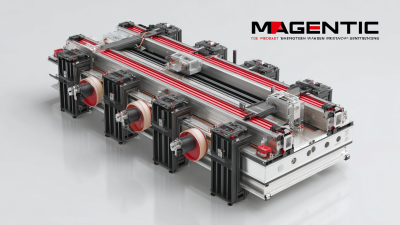

The construction industry has seen a significant shift towards innovative solutions that enhance efficiency and performance, especially in prestressed applications. One such solution is the Magnetic Shuttering System For Prestressed, which has gained traction due to its ability to streamline the formwork process and reduce project timelines. According to a report by the International Journal of Construction Project Management, incorporating advanced formwork systems can lead to a 30% decrease in time spent on concrete setting and a 25% reduction in labor costs. This cutting-edge technology not only boosts productivity but also enhances the quality and durability of precast elements. As the demand for sustainable and cost-effective construction methods continues to rise, understanding the factors that contribute to the successful implementation of the Magnetic Shuttering System For Prestressed is crucial for industry professionals looking to stay ahead in an increasingly competitive market.

Magnetic shuttering systems have emerged as a game-changer in the construction of prestressed concrete structures. One of the primary benefits of using these systems is the substantial increase in efficiency during the casting process. Traditional shuttering methods often require extensive labor and time for setup and dismantling. In contrast, magnetic shuttering allows for rapid positioning and realignment, significantly reducing man-hours and speeding up project timelines. This efficiency is particularly advantageous on construction sites where time is money and tight deadlines are the norm.

Another key benefit of magnetic shuttering systems is their remarkable precision and adaptability. The flexibility of magnetic forms enables seamless adjustments to accommodate various shapes and designs, ensuring a perfect fit for even the most complex geometries. This adaptability not only minimizes material waste but also enhances the quality of the final product, as the system can maintain consistent dimensions and surface finishes. By leveraging these advantages, contractors can achieve higher standards in prestressed concrete applications, leading to improved structural integrity and durability.

| Dimension | Details | Key Benefits |

|---|---|---|

| Ease of Use | Magnetic shuttering systems are easy to assemble and disassemble, reducing labor time. | Saves labor costs and time. |

| Flexibility | Highly adaptable to various shapes and sizes of concrete structures. | Enables customized construction solutions. |

| Quality of Finish | Provides a smooth and even surface finish for prestressed concrete. | Enhances aesthetic appeal and structural integrity. |

| Weight | Lightweight design makes it easy to transport and handle on site. | Reduces logistic costs and physical strain on workers. |

| Cost Efficiency | Initial investment is balanced by long-term savings through reuse. | Improves overall project profitability. |

| Safety | Reduces the risk associated with heavy formwork systems. | Promotes a safer work environment. |

When implementing a magnetic shuttering system for prestressed applications, focusing on essential components is crucial for ensuring an effective setup. One of the most vital elements is the selection of high-quality magnetic panels that provide optimal adhesion to the formwork. This not only enhances stability but also ensures precise alignment during the placement of concrete. Additionally, investing in robust lifting equipment designed for handling the weight of your shuttering will improve the overall safety and efficiency of your project.

Tip: Always conduct a detailed analysis of the formwork types you plan to utilize, considering factors such as cost and installation time. Techniques like value engineering can be instrumental in comparing conventional and semi-system formwork, especially when examining costs associated with columns, beams, and floor slabs.

Designing for modularity can also significantly streamline your project. Modular components allow for flexibility and rapid adjustments, providing significant time savings on site. Using imaginative formwork solutions can lead to more innovative designs, enabling the construction of complex structures, such as prestressed bridge decks, efficiently and effectively.

Installing a magnetic shuttering system for prestressed applications can significantly streamline your construction process. This step-by-step installation guide outlines the essential stages to ensure a successful setup. Begin by preparing your site; clean the area thoroughly, removing any debris that may interfere with the shuttering system. Next, assess the dimensions of the structure you plan to construct to determine the required size and configuration of the magnetic panels. Ensuring accurate measurements is crucial for a seamless installation.

Once your site is prepped and measurements verified, it’s time to position the magnetic shuttering panels. Start by securing the panels to the formwork, making sure they are aligned correctly and maintain a tight fit against surfaces. Carefully check that the magnets are functioning properly, as these are essential for holding the panels in place during pouring. After setting the panels, proceed with the prestressing process; this involves placing the steel tendons and applying the necessary tension before the concrete is poured. By following these steps diligently, you can achieve a smooth installation process that enhances both the efficiency and the quality of your prestressed concrete structures.

Implementing a magnetic shuttering system for prestressed applications can significantly enhance construction efficiency, but it comes with its own set of challenges. One common issue is the initial alignment of the magnetic panels. If not properly installed, misalignment can lead to gaps that compromise the structural integrity of the prestressed elements. To address this, it is crucial to conduct thorough site inspections and utilize precise measuring tools during the setup phase. Ensuring that the panels are positioned accurately will result in a smooth pour and a uniform finish.

Another significant challenge is the variability in magnetic strength, which can affect the holding force of the shuttering. In high-stress applications, the force exerted on the panels can cause slippage if the magnetic fields are not sufficiently strong. The solution lies in selecting high-quality magnets and routinely testing their performance throughout the construction process. Additionally, environmental factors such as temperature and moisture can impact magnetic efficiency, so it's essential to monitor these conditions and adapt the materials accordingly. By proactively addressing these challenges, the implementation of magnetic shuttering systems can be streamlined, leading to enhanced project outcomes.

When it comes to maintaining magnetic shuttering systems in prestressed applications, adherence to best practices is crucial for ensuring optimal performance and longevity. Regular inspection of the magnetic components should be prioritized, as any wear or demagnetization can significantly impact the system's effectiveness. Technicians should assess the integrity of magnetic seals and check for any debris or contaminants that may disrupt their function. Establishing a routine maintenance schedule can help identify issues early and keep the system operating efficiently.

In addition to inspections, proper cleaning procedures are vital. Magnetic shuttering systems should be cleaned with non-abrasive materials to prevent scratches that could affect magnetization. Using gentle, chemical-free solutions helps preserve the quality of the magnetic surfaces. It's also important to monitor environmental factors such as temperature and humidity, as extreme conditions can adversely affect the magnetic properties. By following these best practices, operators can ensure that their magnetic shuttering systems remain reliable and effective in prestressed applications, ultimately leading to safer and more efficient construction processes.