In recent years, the demand for innovative solutions in construction has surged, leading to a growing interest in materials that enhance efficiency, sustainability, and performance. One such advancement is the Neodymium Precast Concrete Magnet, which is revolutionizing the way precast concrete is utilized across various industries.

According to a report by the Global Construction Materials Market, the precast concrete sector is projected to reach a value of $200 billion by 2026, highlighting significant growth and the necessity for improved materials. Neodymium magnets, known for their exceptional strength and durability, when integrated into precast concrete applications, offer unique benefits, including reduced assembly times, enhanced structural integrity, and increased worker safety.

As construction professionals seek to meet the challenges of modern building projects, the implementation of Neodymium Precast Concrete Magnets could very well redefine industry standards, paving the way for safer and more efficient construction methods.

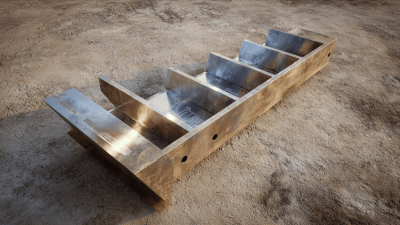

The integration of neodymium magnets into precast concrete structures is a groundbreaking innovation that enhances both functionality and design. Neodymium magnets, known for their exceptional strength and versatility, can be employed in various ways to improve the efficiency of precast concrete applications. One prominent use is in the assembly of precast components, where magnets facilitate quick and precise alignment, reducing labor time and improving accuracy during installation. This method not only speeds up the construction process but also minimizes the potential for human error.

The integration of neodymium magnets into precast concrete structures is a groundbreaking innovation that enhances both functionality and design. Neodymium magnets, known for their exceptional strength and versatility, can be employed in various ways to improve the efficiency of precast concrete applications. One prominent use is in the assembly of precast components, where magnets facilitate quick and precise alignment, reducing labor time and improving accuracy during installation. This method not only speeds up the construction process but also minimizes the potential for human error.

Another innovative application lies in the field of seismic resilience. By incorporating neodymium magnets into the connections between precast elements, engineers can create structures that better absorb and dissipate seismic forces. This approach enhances the overall stability and durability of buildings in earthquake-prone areas, making them safer for occupants. Additionally, these magnets can be used in responsive systems that actively adapt to environmental changes, further revolutionizing the way we think about stability and safety in precast concrete design.

The integration of neodymium magnet technology into precast concrete applications is revolutionizing the way we approach structural stability. Neodymium magnets, known for their exceptional strength and durability, offer innovative solutions that enhance the performance of precast concrete structures. By embedding these powerful magnets within the concrete components, builders can significantly improve the alignment and integrity of connections between elements, reducing the likelihood of structural failure caused by misalignment or shifting.

This technology not only bolsters the safety of constructions but also streamlines the assembly process. With neodymium magnets, precast panels can be quickly and securely positioned during installation, minimizing labor costs and construction time. Moreover, the magnetic connection allows for easier reconfiguration of prefabricated structures, making them adaptable to evolving design requirements. As the construction industry increasingly seeks sustainable and efficient building methods, the use of neodymium magnets in precast concrete signifies a leap toward smarter, more resilient infrastructure solutions.

The integration of neodymium magnets into precast concrete design represents a remarkable leap in the realm of prefabrication. With advancements in coating technology, such as the development of self-healing coatings that enhance the durability of Nd-Fe-B magnets, these magnets are now more resilient to harsh environmental conditions. Research suggests that this innovative approach can significantly increase the structural integrity and longevity of precast components, paving the way for more efficient building solutions.

Furthermore, incorporating powerful permanent magnets into construction not only optimizes material usage but also allows for the design of more versatile and adaptable structures. The impact of neodymium magnets can be transformative, potentially reducing the overall footprint of building core areas, much like the recent innovations in elevator designs that minimize space allocation for shafts. As industries continue to explore the synergies between magnet technology and concrete applications, projections indicate that by 2025, the global market for magnetic materials, including neodymium, is expected to reach USD 31.09 billion, underscoring the growing relevance of this field in modern construction and design methodologies.

This chart illustrates the potential applications of Neodymium magnets in precast concrete design, showcasing various innovative applications and their respective efficiency gains in construction and design processes.

The integration of neodymium magnets in precast concrete applications presents a promising avenue for sustainable construction practices. According to a report by the Global Cement and Concrete Association, the cement industry accounts for approximately 8% of global carbon dioxide emissions. By incorporating neodymium magnets into precast concrete, builders can enhance the efficiency and precision of construction processes, ultimately reducing waste and energy consumption. Neodymium magnets facilitate the alignment and assembly of structural components, minimizing the time and resources needed for traditional fastening methods.

Furthermore, innovative uses of neodymium magnets can lead to enhanced recycling opportunities within construction. A study from the Journal of Cleaner Production highlights that utilizing magnetic technology can significantly improve the separation and recovery of concrete waste. This is essential for achieving circular economy goals in the construction sector, where the potential for recycling concrete could reach as high as 50% with effective magnet-based separation systems. By championing eco-friendly practices through the integration of neodymium magnets, the construction industry can move towards a sustainable future, reducing its environmental footprint while maintaining structural integrity and performance.

Neodymium magnets have emerged as a transformative force in the construction industry, allowing for innovative applications that significantly enhance project efficiency and structural integrity. Several case studies highlight their successful implementation, showcasing the versatile benefits they provide. For instance, in a recent commercial building project, neodymium magnets were utilized to facilitate pre-cast concrete panel installation. This technology not only streamlined the assembly process but also ensured precise alignment, reducing labor costs and construction time.

Another compelling example is the use of neodymium magnets in bridge construction. An engineering firm employed these magnets to secure temporary structures during the assembly of large segments. This method enabled a safer working environment by reducing the need for traditional fasteners, thus minimizing the risk of accidents on site. The effective use of neodymium magnets in these projects illustrates their potential to revolutionize construction practices by introducing innovative solutions that enhance both safety and efficiency.

| Project Name | Location | Application | Benefits | Year Implemented |

|---|---|---|---|---|

| Urban Bridge Project | New York, USA | Precast Concrete Components | Improved structural integrity and reduced weight | 2021 |

| Residential Tower | Toronto, Canada | Magnetic Fastening Systems | Faster construction and enhanced durability | 2020 |

| Commercial Complex | London, UK | Magnetically Lifting Panels | Enhanced safety and reduced labor costs | 2019 |

| Highway Overpass | Sydney, Australia | Self-Aligning Concrete Sections | Improved alignment accuracy and reduced installation time | 2022 |

| Industrial Facility | Berlin, Germany | Magnetically Secured Wall Panels | Improved energy efficiency and environmental sustainability | 2023 |