In the precast concrete industry, the efficiency and precision of production are paramount, making the choice of equipment critical. Among the essential tools, shuttering magnets for precast production stand out for their ability to streamline the casting process. According to recent industry reports, the demand for precast concrete products is projected to grow at a CAGR of 6.5% through 2025, driven by increased urbanization and infrastructure development. The effectiveness of shuttering magnets directly impacts the quality and turnaround time of precast components, with studies showing that using high-quality magnets can reduce labor costs by up to 30% and improve production cycle times significantly. This guide aims to navigate the complexities of selecting the right shuttering magnets, ensuring that your operations remain competitive and efficient in an evolving market.

Shuttering magnets play a crucial role in precast production by securely holding formwork in place during the casting process. These powerful magnets ensure precision in mold alignment and stability, helping to achieve high-quality concrete components. Understanding the types and applications of shuttering magnets can greatly enhance the efficiency and effectiveness of your production line.

When selecting shuttering magnets, consider the specific requirements of your project. For instance, high-tensile strength magnets are ideal for thicker formwork, while lighter options work well for smaller, intricate molds. Additionally, assess the environmental conditions of your production site, as factors like moisture and temperature can impact magnet performance.

Tips for optimal usage of shuttering magnets include regular maintenance checks to ensure they remain clean and operational. It’s also advisable to use safety equipment when handling heavy magnets to prevent injuries. Lastly, consider investing in adjustable magnetic solutions for versatile applications, allowing you to maximize your production capabilities while minimizing downtime.

When selecting shuttering magnets for precast production, several key factors should guide your choice to ensure efficiency and reliability. First, consider the magnetic strength. A strong magnet is essential for securely holding forms in place under the pressure of concrete. Weak magnets can lead to misalignment and costly production errors. Look for magnets that maintain their grip even under heavy loads, especially as concrete is poured.

Another important factor is the magnet design. Opt for magnets that have a user-friendly design, allowing for easy placement and adjustments during setup. Some magnets come with integrated handles or quick-release mechanisms, making repositioning simple and efficient. This not only speeds up the production process but also enhances safety on site.

Finally, evaluate the durability of the magnets. Precast environments can be harsh, with exposure to concrete, moisture, and varying temperatures. Choose magnets that are designed with robust materials resistant to corrosion and wear. Investing in high-quality shuttering magnets will pay off in the long run, reducing the need for frequent replacements and minimizing downtime in your production line.

Choosing the right shuttering magnets for precast production is crucial for ensuring efficiency and quality in concrete forming. When evaluating high-quality shuttering magnets, particularly those manufactured in China, there are several key features to consider. First and foremost, the strength of the magnet is essential, as it directly impacts the stability of the formwork. High-quality magnets should exhibit strong holding power to prevent displacement during the concrete pouring process. Additionally, the durability of the materials used in production is critical for longevity, ensuring that the magnets can withstand the rigorous environment of precast operations.

The global market for magnetic devices, including those utilized in construction, is projected to grow significantly, with values expected to reach USD 658.5 million by 2025. However, the recent import restrictions imposed by China on key metals and magnets highlight potential challenges for manufacturers worldwide. The implications of these restrictions are profound, as they disrupt supply chains and force companies to seek alternatives. Automakers, for instance, are urgently exploring ways to mitigate the risks associated with dependency on rare-earth magnets sourced from China, showcasing the broader impact of magnet supply issues on various sectors. Operating amidst these challenges, it's vital for businesses to select shuttering magnets that not only meet performance standards but also remain resilient amidst fluctuating market conditions.

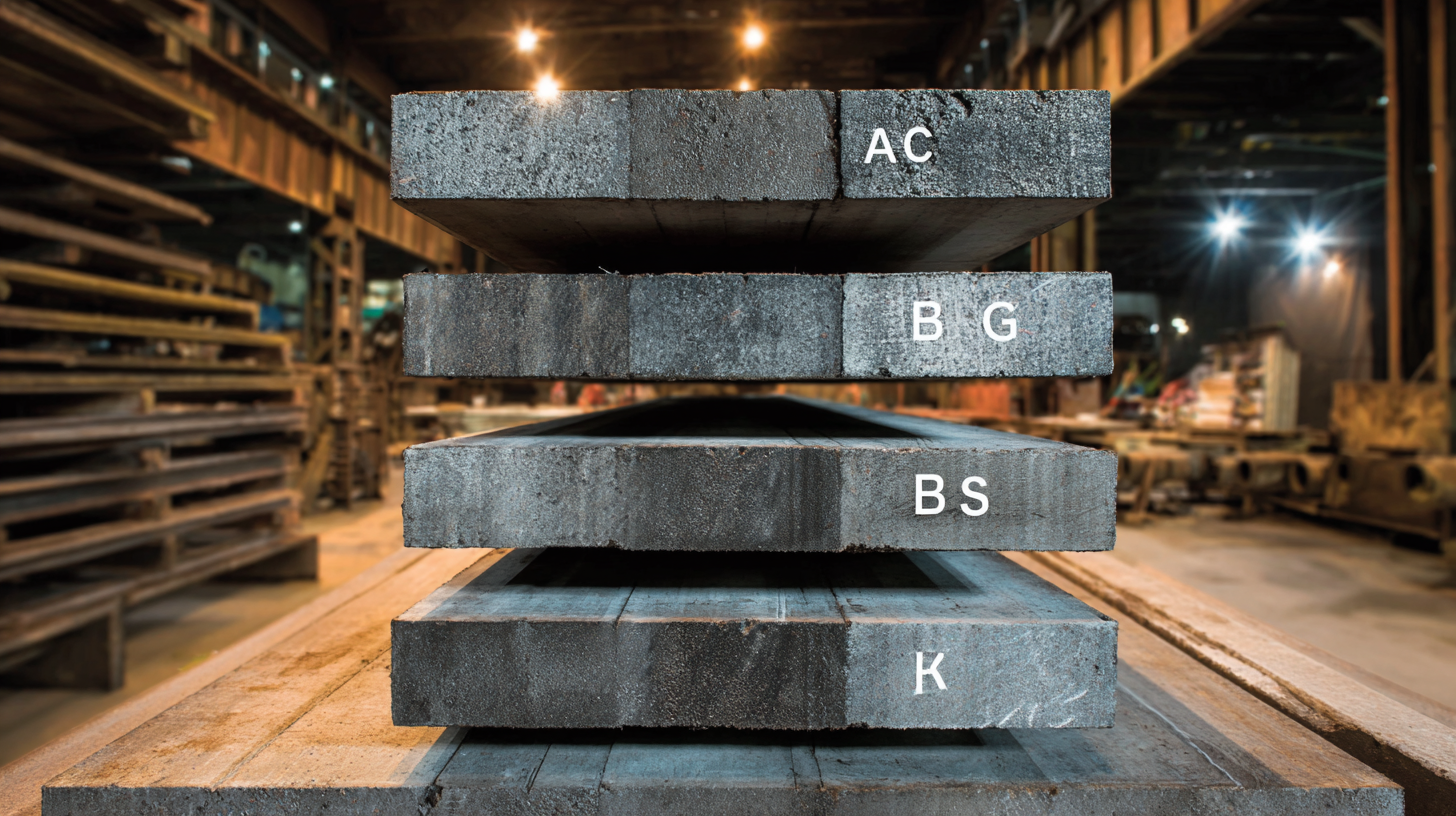

When it comes to precast production, selecting the right shuttering magnets is crucial for achieving optimal efficiency. Various types of shuttering magnets exist on the market, each designed with unique features to cater to different manufacturing needs. For instance, some magnets offer high pull strength, which is essential for securing formwork in large-scale applications, while others might focus on quick release mechanisms, facilitating faster assembly and disassembly of molds.

Incorporating innovative technologies in manufacturing processes can further enhance productivity. Just as the automotive industry is evolving with electric vehicle motors that minimize reliance on rare earth elements, the construction sector can benefit from advancements in magnetic materials for shuttering solutions. By exploring the comparative benefits of different magnet types, companies can make informed choices that not only improve efficiency but also align with sustainable practices.

Utilizing efficient magnetic systems can drive the precast industry forward, paving the way for a greener approach to construction.

When it comes to the maintenance and long-term use of shuttering magnets in precast production, understanding the best practices can significantly enhance their performance and durability. Regular inspection of the magnets is essential; studies indicate that magnets in consistent use can experience a decline in holding strength of up to 20% if not properly maintained. This can lead to production inefficiencies and increased costs. Cleaning the magnets with a non-corrosive solution after every use ensures they remain free of debris and contaminants that could impair functionality.

In addition to regular cleaning, proper storage is crucial for prolonging the life of shuttering magnets. According to industry reports, storing magnets in a dry, temperature-controlled environment can reduce the risk of rust and demagnetization, both of which are common issues that affect magnet integrity over time. Utilizing magnetic slings or cases for transport can also protect these tools from physical damage during handling.

Adopting these maintenance practices not only boosts the operational efficiency of your precast production but also enhances safety by ensuring that magnetic systems function as intended without unexpected failures.