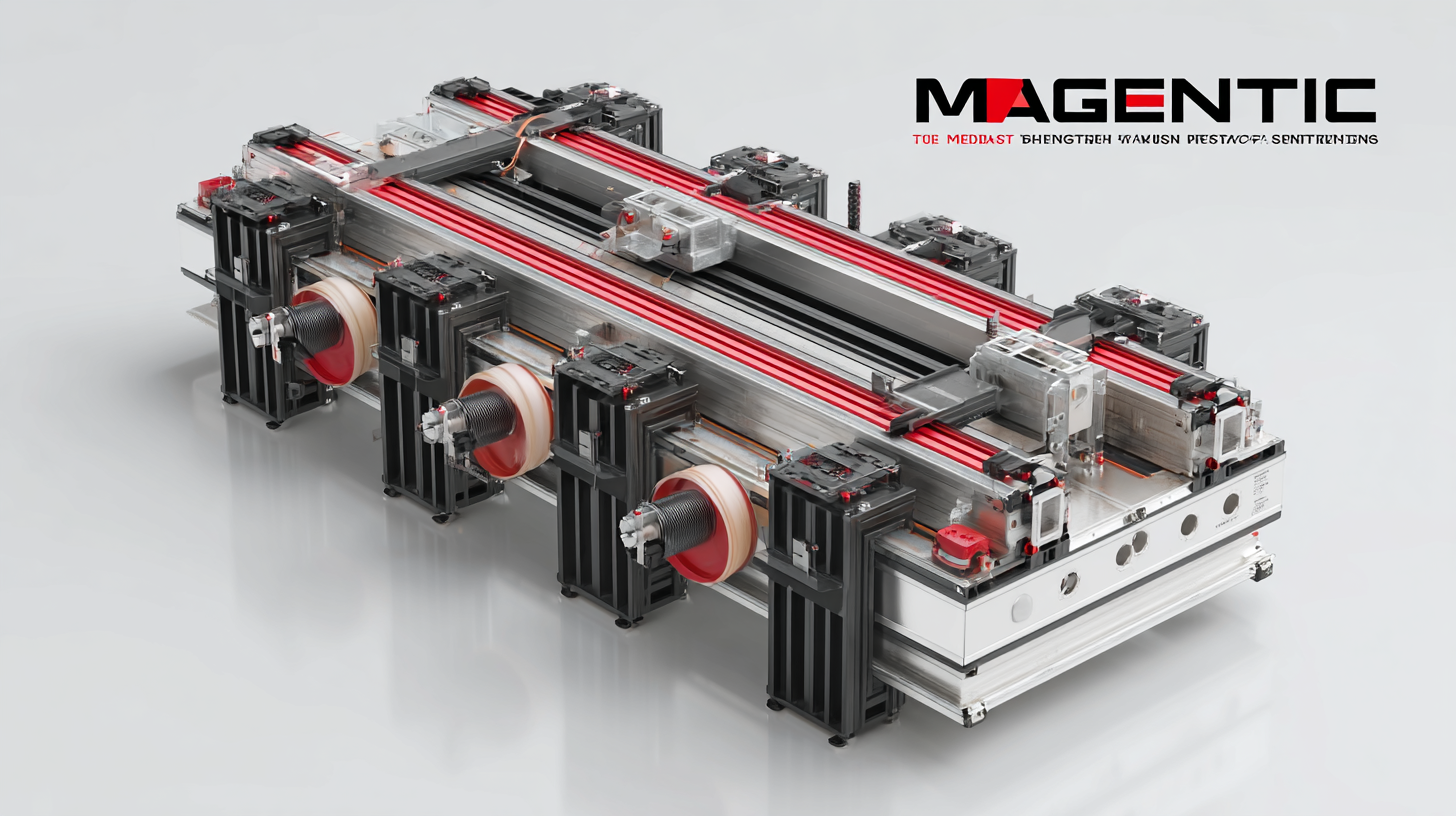

As we look toward the future of construction, particularly in the realm of prestressing, the emergence of innovative technologies will play a pivotal role in shaping industry standards. One of the most exciting advancements on the horizon is the use of the Magnetic Shuttering System for Prestressed applications. This cutting-edge approach not only enhances the efficiency and accuracy of formwork placement but also offers unprecedented flexibility and reusability, addressing many of the challenges faced in traditional shuttering systems. In this blog, we will explore the future trends expected by 2025, detailing essential factors that construction professionals should consider when integrating the Magnetic Shuttering System into their prestressing projects. Join us as we present a comprehensive checklist to ensure your construction methods are aligned with the latest advancements and best practices in the field.

The construction industry is on the brink of a transformation, particularly in the field of prestressing construction. As we approach 2025, innovative technologies such as magnetic shuttering systems are paving the way for enhanced efficiency and precision in construction practices. According to a recent report by MarketsandMarkets, the global prestressed concrete market is projected to grow from USD 15.5 billion in 2020 to USD 25.8 billion by 2025, highlighting the growing demand for more effective construction solutions.

One of the key innovations driving this shift is the implementation of magnetic shuttering systems. These systems not only reduce labor costs but also improve safety on job sites. They allow for quicker assembly and disassembly, minimizing downtime and maximizing productivity. A study by McKinsey & Company found that construction efficiency could improve by 50% through the adoption of advanced technologies and streamlined processes.

**Tip:** When considering magnetic shuttering systems, focus on selecting designs that enhance adaptability and reusability to further optimize resource allocation.

Furthermore, sustainability is becoming a fundamental pillar of prestressing construction. Eco-friendly materials and practices are being prioritized as companies strive to meet future regulatory requirements and consumer expectations. By 2025, we can expect to see a more significant integration of sustainable methods, with a focus on reducing waste and carbon footprints in all construction phases.

**Tip:** Evaluate the lifecycle of materials used in your projects to ensure they align with sustainable practices, thereby contributing to a greener construction sector.

The construction industry is on the brink of a transformation, with magnetic shuttering systems emerging as a pivotal element in modern construction processes. These systems offer unparalleled efficiency and flexibility, crucial in addressing the labor shortages affecting the sector. Research indicates that technology, especially innovative construction techniques, plays a critical role in enhancing job capabilities rather than replacing the workforce. As noted in recent studies, a focus on combining cost-effective materials with advanced systems like magnetic shuttering can streamline operations, achieving quicker assembly times and increased project viability.

Moreover, the integration of AI-driven technologies is set to enhance knowledge co-construction within teams, fostering collaboration and improving project outcomes. For instance, embracing AI in construction management is reported to significantly reduce project costs while enhancing accuracy in cost estimations. As cost engineers become central figures in project planning, the role of cutting-edge materials and construction systems, including magnetic shuttering, becomes ever more critical in democratizing access to quality architecture. These advancements not only promise to boost productivity but also to reshape the roles of professionals in the industry, emphasizing the need for adaptability and continuous learning in a rapidly evolving landscape.

The construction industry is constantly evolving, and magnetic shuttering systems are poised to play a vital role in shaping the future of prestressing construction by 2025. Unlike traditional shuttering methods that often require extensive labor and materials, magnetic shuttering offers a number of advantages that enhance efficiency and effectiveness. For instance, the ability to quickly set up and reposition magnetic forms can significantly reduce construction time, allowing for more agile project management and timely completion of tasks.

Additionally, magnetic shuttering systems improve the quality of the end product by providing precise and consistent formwork shapes. This precision not only ensures accurate dimensions for prestressed elements but also minimizes the potential for defects that can arise from shifting or misaligned forms. Moreover, as the use of permanent formwork systems for single dwelling wall construction gains traction, the enhanced durability and stability of magnetic systems compared to traditional methods make them an attractive option for builders looking to innovate while maintaining structural integrity. As the industry embraces these cutting-edge technologies, the benefits of magnetic shuttering will likely become even more pronounced, setting new standards for construction practices.

As the prestressing construction industry moves towards 2025, evolving standards and regulations will significantly impact the adoption and implementation of new technologies, particularly in magnetic shuttering systems. According to a recent industry report by Grand View Research, the global prestressing system market is projected to grow at a CAGR of 6.5% from 2021 to 2028, highlighting the urgency for compliance with forthcoming regulations addressing safety and sustainability in construction practices. Stricter guidelines are anticipated from organizations such as the International Organization for Standardization (ISO) and local governing bodies, which will mandate enhanced quality assurance protocols in prestressing technologies.

When integrating new systems like magnetic shuttering, it’s crucial to stay informed about regulatory changes and their implications on design and construction processes. **Tip**: Ensure that your team is trained regularly on the latest standards and that you invest in technology that simplifies compliance with these regulations to maintain a competitive edge.

Additionally, the move towards eco-friendly practices will drive the development of innovative materials and techniques in prestressing. An advanced study by McKinsey & Company suggests that construction firms that adopt green technologies can enhance their operational efficiency by up to 15%. **Tip**: Assess your current materials and consider replacements that meet new environmental standards, enhancing both compliance and sustainability in your projects.

This chart illustrates the projected adoption rate of magnetic shuttering systems in prestressing construction from 2021 to 2025. As technology advances and regulations evolve, significant growth in adoption is anticipated, highlighting the increasing importance of efficiency in construction practices.

The construction industry is witnessing a transformative shift shaped by emerging trends in prestressing construction practices. As modular construction gains traction, with projected growth driven by both permanent and relocatable options, the demand for innovative materials and techniques is at an all-time high. The India precast concrete market is a prime example, estimated to expand from USD 6.69 billion in 2024 to USD 17.37 billion by 2033, fueled by increasing urbanization and infrastructural projects.

In this dynamic environment, the integration of advanced technologies like Additive Manufacturing (AM) and Building Information Modeling (BIM) is paving the way for enhanced efficiency and precision in construction processes. These methodologies not only streamline project execution but also optimize resource management. The application of artificial intelligence in developing advanced construction materials, such as fiber-reinforced composites, is further revolutionizing the industry, allowing for smarter and more sustainable building practices as we move toward 2025.