In the rapidly evolving landscape of the precast concrete industry, the introduction of innovative technologies such as the Electric Box Insert Magnet for Precast Concrete Production is reshaping manufacturing processes. As the demand for efficient and reliable solutions grows, industry experts like Dr. Emily Johnson, a leading authority in precast concrete technologies, emphasize the significance of these advancements. Dr. Johnson states, “Utilizing the Electric Box Insert Magnet streamlines our operations, enabling us to achieve higher precision and faster turnaround times in production.”

The Electric Box Insert Magnet plays a crucial role in facilitating the placement of electrical boxes within precast concrete components. Its design allows for effortless alignment and secure fastening, significantly reducing labor costs and enhancing productivity. As manufacturers look towards 2025 and beyond, the integration of such magnet systems is not only deemed advantageous but essential for maintaining competitive edges in a demanding market.

Furthermore, this innovative tool contributes to improved safety and quality control within the production environment. With its ability to ensure precise positioning of electrical inserts, the Electric Box Insert Magnet for Precast Concrete Production promises to revolutionize how precast components are manufactured, paving the way for more efficient and sustainable building practices. As we delve deeper into this subject, it is crucial to explore how these advancements can be properly implemented to maximize their benefits in the precast industry.

Electric box insert magnets play a crucial role in the precast concrete production process, enhancing efficiency and ensuring precision. These magnets are specifically designed to securely hold electric boxes in place during the casting of concrete. By providing a reliable attachment point, they eliminate the need for additional forms or supports, allowing for quicker setup and reduced labor costs. As the precast industry evolves in 2025, understanding the functionalities and benefits of these insert magnets becomes essential for manufacturers striving to improve output and quality.

When employing electric box insert magnets, it's important to ensure proper placement and alignment. Misalignment can lead to electrical box placement issues, compromising the integrity of the final product. One tip for optimal use is to perform a thorough inspection of magnets before each use, checking for any wear or damage that could affect their holding power. Additionally, applying the magnets at the correct height can facilitate easier access and installation of electrical components post-casting.

Furthermore, consider the size and strength of the magnets based on the specific requirements of your concrete project. Using magnets that are too weak for larger boxes could result in failures during the curing process. To enhance stability, always ensure the concrete mix is appropriately adjusted to accommodate the weight and position of the embedded boxes. Keeping these tips in mind will help in maximizing the efficiency and reliability of electric box insert magnets in precast concrete production.

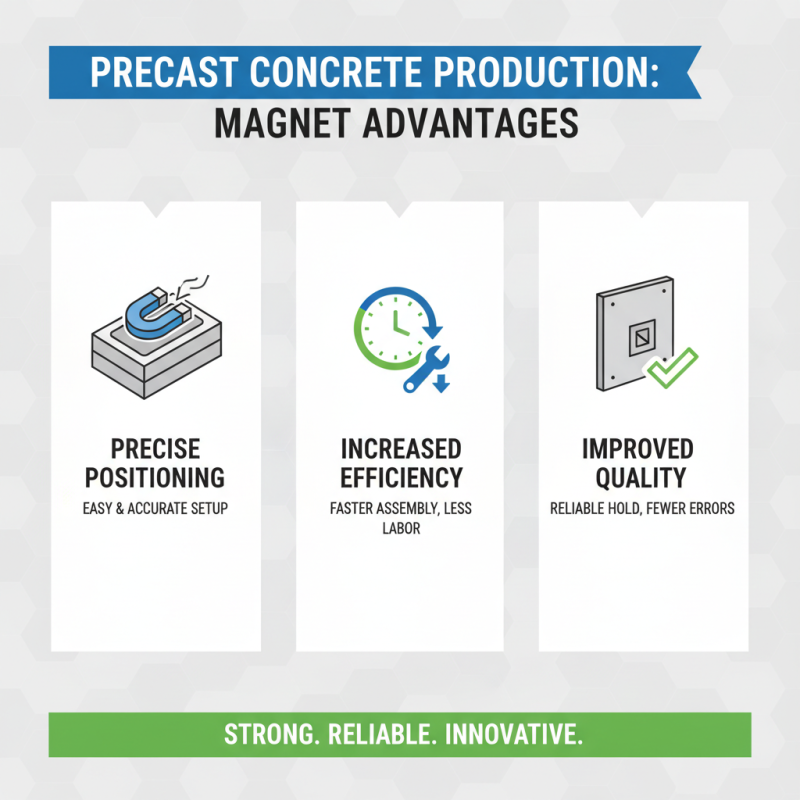

The use of electric box insert magnets in precast concrete production offers numerous advantages that enhance both the efficiency and quality of the manufacturing process. One of the most significant benefits is the ease with which these magnets allow for precise positioning of inserts within the mold. This innovative approach streamlines the setup phase, reducing labor time and minimizing the risk of errors during assembly. By providing strong, reliable holding power, electric box insert magnets enable manufacturers to focus on creating high-quality precast elements without the hassle of traditional fastening methods.

In addition to efficiency, the application of electric box insert magnets contributes to improved safety on the production floor. The elimination of cumbersome mechanical fasteners translates to a cleaner and more organized workspace, reducing the likelihood of injuries related to handling sharp or heavy tools. Furthermore, the quick-release mechanism of these magnets allows workers to adjust or reposition inserts swiftly and safely, promoting a more dynamic work environment. This combination of safety and efficiency not only boosts productivity but also enhances the overall quality of the precast concrete products, making them more competitive in the market.

Using electric box insert magnets in precast concrete production offers numerous benefits, including increased efficiency and reduced labor costs. To successfully implement this technology in your production process, follow this step-by-step guide. First, it’s essential to understand the design specifications of the electric box insert magnets you plan to use. Check their loading capacity and compatibility with your existing molds, ensuring they are suitable for your specific precast concrete applications.

Next, installation is critical. Begin by cleaning the mold surfaces to ensure optimal adhesion. Position the electric box insert magnets carefully, following the manufacturer's guidelines, to achieve the best performance and secure attachment to the concrete. Once the magnets are in place, test their strength using small concrete samples. This initial test will help validate the magnets' effectiveness and make necessary adjustments before scaling up to larger production runs.

**Tips**: Always ensure that you have proper safety measures in place when handling electric box insert magnets, as improper handling can lead to accidents. Additionally, regularly check the condition of the magnets and their electrical components to guarantee consistent performance throughout the production process. Keeping a maintenance log can help track any issues that may arise and prolong the lifespan of your equipment.

When utilizing electric box insert magnets in precast concrete production, safety should always be a primary concern. Magnets can pose unique hazards, especially when working in industrial environments where heavy machinery and materials are involved. Proper training and awareness are essential to mitigate the risks associated with magnet use. Workers should be informed about the potential for pinching injuries and should always manage magnets carefully to avoid accidents. Additionally, it is crucial to ensure that magnetic properties are clearly communicated on-site to prevent any unexpected interactions with other metallic objects.

In addition to worker safety, the operational environment must be conducive to safe magnet usage. This includes ensuring a clean workspace where debris and other materials that could interfere with the magnets are kept at bay. Protective equipment, such as gloves and safety goggles, should be worn to prevent injuries from accidental drops or equipment failures. Furthermore, conducting regular inspections of the magnets and related equipment can help identify any wear and tear that could compromise safety. By implementing these considerations, the risks associated with using electric box insert magnets in concrete production can be significantly minimized, leading to a safer and more efficient working environment.

| Safety Consideration | Importance Level | Recommended Practice |

|---|---|---|

| Worker Training | High | Provide comprehensive training on magnet safety and handling. |

| Magnet Inspection | Medium | Regularly inspect magnets for damage or wear. |

| Personal Protective Equipment | High | Ensure all workers wear appropriate PPE when handling magnets. |

| Clear Work Area | Medium | Keep the work area free of clutter to avoid accidents. |

| Emergency Procedures | High | Establish and communicate emergency response procedures. |

As precast concrete production continues to evolve, the integration of

Electric Box Insert Magnet (EBIM)

technology is set to revolutionize manufacturing processes by

2025. Recent industry reports

indicate that the global precast concrete market is expected to reach

approximately $150 billion by 2025, with a significant portion

attributed to advancements in magnet technologies that enhance operational efficiency.

These magnets facilitate quicker setup times and improved accuracy in insert placement,

significantly reducing material waste and labor costs.

Moving into 2025, notable trends

in EBIM technology will likely focus on improved energy efficiency and automation capabilities.

Reports suggest that manufacturers are increasingly adopting energy-efficient magnets that

not only reduce power consumption but also offer better performance longevity. Moreover,

automation in concrete production is expected to rise, with magnets designed for seamless

integration into robotic systems that handle complex tasks with precision. By harnessing these

advancements, producers can expect higher output rates and greater flexibility in design, catering

to an increasingly diverse range of project requirements in the construction sector.