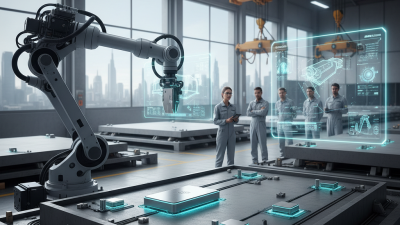

In the precast concrete industry, efficiency and precision are paramount. The "Electric Box Insert Magnet For Precast Concrete Production" plays a crucial role in achieving these goals. Expert Mark Thompson, a renowned figure in the field, once said, “The right tools can transform the production process.” This sentiment underscores the importance of innovative solutions like magnetic inserts.

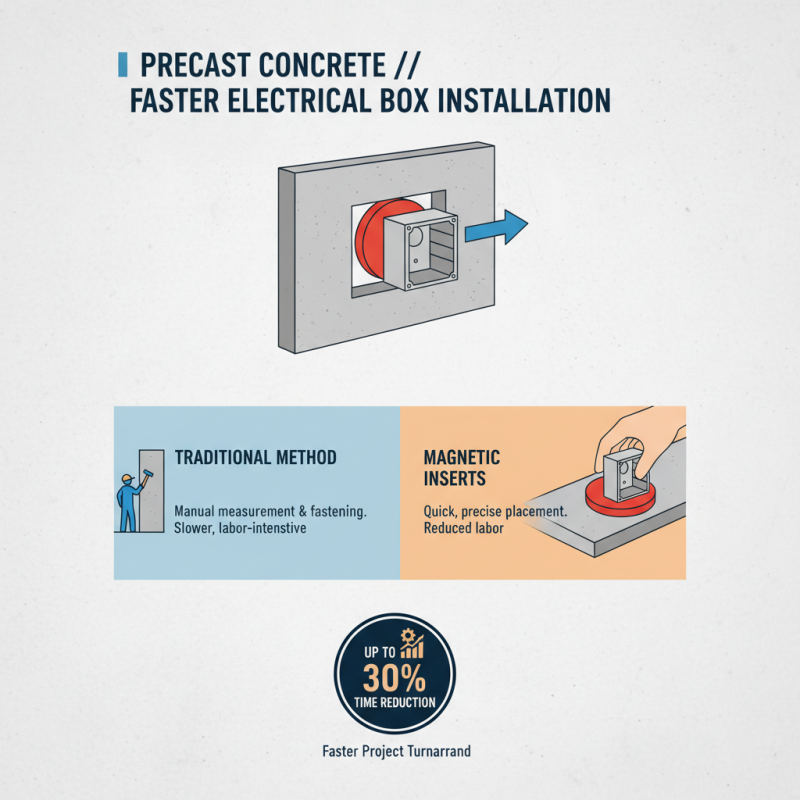

Magnetic inserts simplify the installation of electrical boxes in precast elements. They offer a reliable way to secure boxes during the concrete setting process. This reliability reduces errors and waste. However, not every project may benefit equally from their use. The effectiveness of the Electric Box Insert Magnet can vary, depending on the specific design and application.

Industry professionals must evaluate each project carefully. They should consider the balance between cost and efficiency. While magnets can enhance production speed, over-reliance on technology can lead to oversight of essential manual verification processes. In a field where precision is key, acknowledging these potential pitfalls is crucial for continuous improvement.

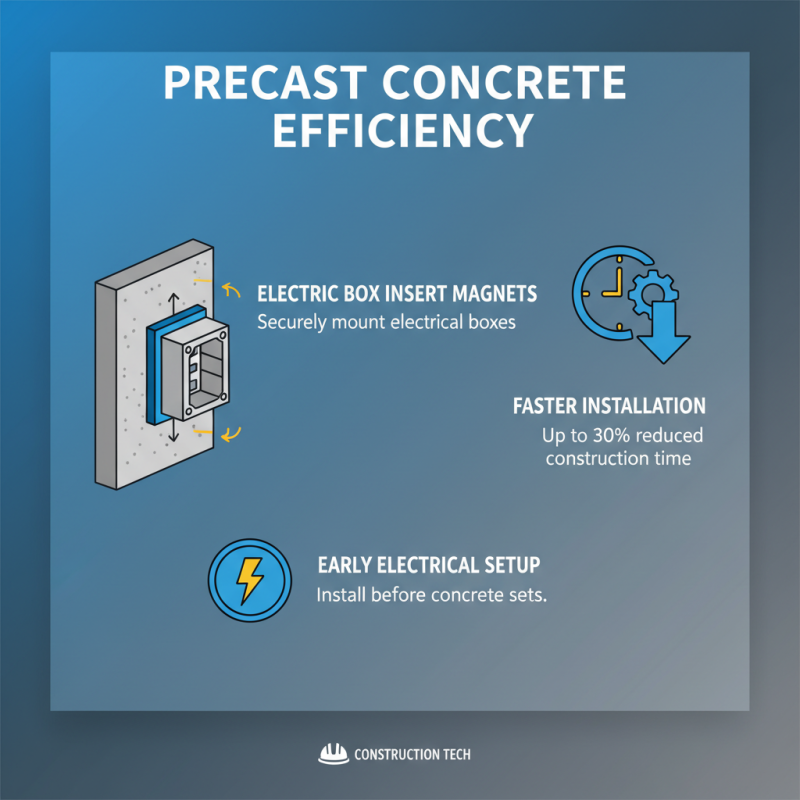

Electric box insert magnets are crucial for precast concrete applications. They facilitate mounting electrical boxes within concrete elements, ensuring they are securely embedded during the casting process. This method has been increasingly adopted due to its efficiency. According to industry reports, precast concrete structures can reduce construction time by up to 30%. This efficiency stems from the ability to get electrical installations done before the concrete is even set.

When using electric box insert magnets, accuracy is key. Each magnet's position matters. Misplacement can lead to challenges later when installing electrical components. It's essential to conduct thorough checks before the pouring process. Ensure every insert is level and correctly aligned. Any oversight can result in costly adjustments.

Tips: Always double-check the insert positioning before concrete pours. Consider using a template for consistent placements. Regularly inspect magnets for wear and tear; old magnets might not hold securely. These small steps can enhance the overall quality of your precast concrete projects. Balancing efficiency with precision in each step is vital.

Electric box insert magnets are essential in precast concrete construction. They help secure electrical boxes within the concrete panels. These magnets hold the boxes firmly in place during the casting process. This ensures proper alignment and positioning for future electrical installations.

The functionality of these magnets is impressive. They can withstand significant weight and pressure. Once the concrete cures, the magnets make removal easier for further installation. However, if not positioned correctly, they can create issues. Misalignment might lead to difficult adjustments later on. Ensuring precise placement is crucial.

The use of electric box insert magnets represents an innovative approach in construction. They save time and resources. Yet, like any tool, they require careful handling. The technology is evolving, but challenges remain. Finding the right balance between efficiency and precision is still a work in progress.

| Feature | Description | Benefits |

|---|---|---|

| Material | High-strength steel with corrosion-resistant coating | Increases durability and longevity |

| Magnetic Strength | Powerful magnets provide strong adhesion | Ensures stability during the precasting process |

| Installation | Easy to install within the mold | Reduces labor time and increases efficiency |

| Versatility | Can be used with various precast concrete applications | Flexible design for different project requirements |

| Weight | Lightweight design for easy handling | Facilitates quick installation and repositioning |

| Cost-Effectiveness | Affordable solution for precast applications | Reduces overall project costs |

Electric box insert magnets are gaining traction in precast concrete construction. These tools enhance efficiency during installation, allowing for quicker mounting of electrical boxes. A recent report indicates that using magnets can reduce installation time by up to 30%. This significant decrease leads to faster project turnaround.

One notable advantage is flexibility. Electric box insert magnets can adapt to various designs and configurations. Builders can easily reposition them as needed. This adaptability reduces the chances of costly errors. According to a survey, around 40% of workers noted fewer mistakes when using these magnets. It seems intuitive, but it's easy to overlook.

However, some challenges exist. Not all concrete shapes and sizes have been tested with these magnets. Builders must still assess the specific requirements of each project. Moreover, training workers to use these tools effectively is essential. Without proper guidance, inefficiencies may arise. Balancing speed with precision is crucial in construction. Embracing innovations like electric box insert magnets can streamline processes, but vigilance is necessary in implementation.

Electric box insert magnets serve a crucial role in the precast concrete industry. They ensure the precise positioning of electrical boxes. The installation process is vital for achieving quality control in precast elements. Understanding the right techniques can enhance efficiency on the job site.

The installation begins with selecting the appropriate magnets for the specific weight and type of electric box. A study shows that using high-strength magnets can improve the placement accuracy by 30%. Positioning the magnets requires a steady hand and an eye for detail. Misalignment can lead to costly rework.

Installers should ensure the magnets adhere well to the clean surface of the mold. A clean mold reduces the risk of bubbles and other defects. Onto the assembly, it's important to fix the boxes securely. Improper placement may cause future complications, such as electrical failure. Regular training for workers can minimize these mistakes. Each install should be reviewed for quality. This extra step pays off in the long run.

Electric box insert magnets are vital in the precast concrete industry. They facilitate the safe installation of electrical boxes into concrete structures. With precise placement, these magnets ensure that power sources are properly housed. The application of electric box insert magnets streamlines construction, reducing both time and labor costs.

In the industry, studies show that utilizing these magnets can cut installation time by up to 30%. This efficiency is crucial for large projects, where every minute counts. Common applications include residential buildings, commercial structures, and even infrastructure projects. They provide reliable support for electrical systems, enhancing safety and performance.

Tip: Always verify the weight rating of the magnet before use. Proper rating ensures maximum effectiveness and prevents accidents.

Some contractors overlook the importance of proper placement. Misalignment can result in a need for rework, costing both time and money. Understanding how to effectively use these tools is key. Consistent training and awareness can significantly improve outcomes.

Tip: Regularly review operational procedures with your team. Keeping everyone updated fosters a culture of safety and efficiency.