In an industry characterized by persistent challenges in time management and resource allocation, Magnetic Formwork Products are setting a new standard for efficiency in construction practices. According to a report from MarketsandMarkets, the global formwork market is projected to reach USD 8.7 billion by 2026, driven by an increased adoption of advanced technologies and innovative materials. Magnetic formwork systems not only streamline the construction process but also minimize labor costs and waste, making them an attractive option for project managers aiming for rapid and cost-effective construction solutions. The integration of these products allows for improved accuracy and flexibility in concrete forming, ultimately enhancing project turnaround times. As the construction sector continues to evolve, the implementation of Magnetic Formwork Products signifies a pivotal shift towards a more efficient and sustainable future.

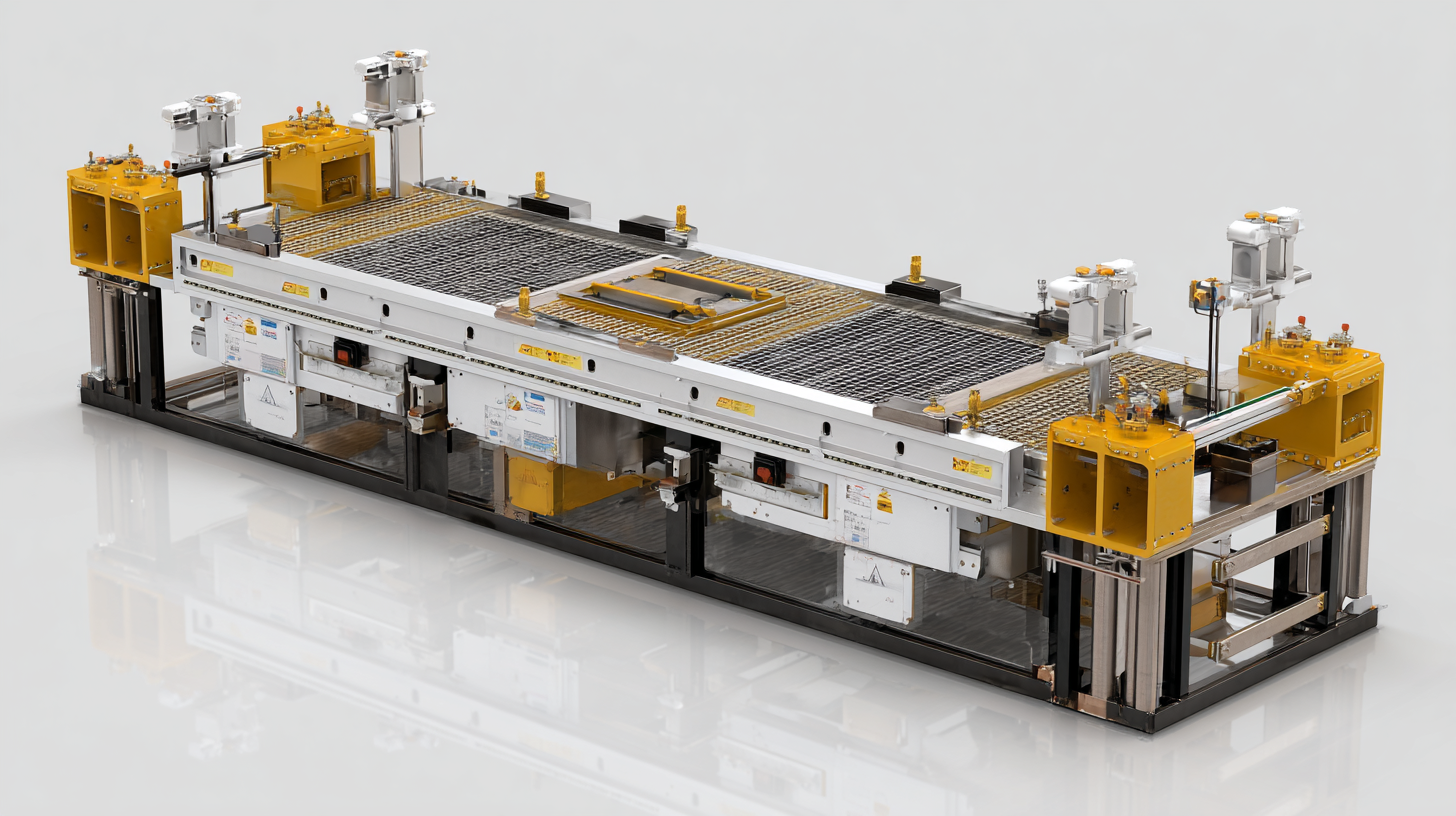

Magnetic formwork technology represents a revolutionary advancement in the construction industry, leveraging the principles of magnetism to create efficient and versatile structures. This innovative method employs magnetized components that easily interlock, allowing for quick assembly and disassembly. The application of magnetism not only speeds up the construction process, but it also enables better precision in shaping concrete elements. As a result, builders can achieve high standards of quality while minimizing waste and labor costs.

One of the primary benefits of magnetic formwork is its adaptability. This technology can be employed in various construction environments, from urban projects to complex architectural designs. The ease of manipulating the magnetic forms enhances creativity and flexibility, allowing engineers and architects to experiment with various shapes and structures. Additionally, magnetic formwork can be reused multiple times, further contributing to sustainability efforts in the construction sector. Overall, the integration of such advanced technologies could pave the way for a more efficient and eco-friendly future in building practices.

Magnetic formwork is revolutionizing construction processes by introducing a level of efficiency and adaptability previously unseen in traditional methods. One key advantage is the speed of installation; magnetic systems can be set up quickly and adjusted easily compared to conventional formwork. This reduction in assembly time allows projects to stay on schedule and cuts down labor costs significantly.

Tip: When considering magnetic formwork for your next project, ensure the magnetic strength is appropriate for the specific applications you're targeting. An excess can lead to difficulties in adjustment, while too little may compromise stability.

Another notable advantage is the flexibility inherent in magnetic formwork designs. Contractors can create complex shapes and curved surfaces effortlessly, giving architects the freedom to innovate without being hampered by rigid formwork constraints. This adaptability not only enhances structural aesthetics but also optimizes material usage, reducing waste.

Tip: Invest in training for your team on the unique handling and setup of magnetic formwork. Proper understanding and techniques can maximize its benefits and ensure safety on-site.

Implementing magnetic formwork products in your construction workflow can significantly enhance efficiency and reduce labor costs. The first step is to assess your current workflow and identify areas where traditional formwork falls short. Magnetic formwork allows for faster setup and repositioning, minimizing the time spent on assembling and dismantling. Start by training your team on the properties and benefits of magnetic formwork to ensure smooth adoption.

Tip: Before full implementation, conduct a pilot project using magnetic formwork. This trial will help you gauge the impact on your project timelines and labor efficiency, allowing for adjustments before scaling up.

Next, integrate magnetic formwork into your project planning. Evaluate how these products can complement your existing tools and techniques. Collaboration with manufacturers can provide insights into custom solutions tailored to your specific needs. By fostering a mindset of innovation, you can better navigate the shift from conventional methods to magnetic systems.

Tip: Engage in regular feedback sessions with your team throughout the transition. This creates an open environment for discussing challenges and celebrating successes, ensuring that all members are on board with the new processes.

Magnetic formwork products are revolutionizing the construction industry by offering a more efficient alternative to traditional formwork solutions. While conventional formwork systems often require extensive labor and materials, magnetic formwork significantly reduces these expenses. According to a report by Grand View Research, the global formwork market is expected to reach $16.5 billion by 2027, driven in large part by innovations that enhance speed and efficiency. Magnetic formwork not only minimizes the time spent on installation but also ensures precise alignment, leading to lower material waste and a reduction in overall project costs.

In comparison to traditional systems, magnetic formwork enables a more flexible design approach, allowing for quick adjustments on-site. The labor-intensive assembly and disassembly processes associated with wooden or steel forms can consume up to 50% more manpower and time, as highlighted by the McKinsey Global Institute. Moreover, with magnetic systems, construction teams can achieve up to 30% faster cycle times, significantly accelerating project completion. This increased efficiency, paired with the enhanced durability and reusability of magnetic formwork, positions it as a transformative player in the future of construction, promising to not only enhance productivity but also foster sustainability within the industry.

| Feature | Magnetic Formwork | Traditional Formwork |

|---|---|---|

| Setup Time | Reduced by 50% | Standard |

| Labor Requirements | Less labor-intensive | More labor-intensive |

| Reusability | High (up to 100 times) | Limited (20-30 uses) |

| Material Cost | Moderately high | Lower |

| Design Flexibility | Highly flexible | Less flexible |

| Environmental Impact | Lower waste generation | More waste generation |

| Speed of Construction | Faster | Slower |

The future of construction is being revolutionized by innovative magnetic formwork technology, which promises to enhance efficiency and precision in the building process. One of the most significant trends is the integration of smart materials that respond to environmental conditions. These advanced magnetic formwork products not only streamline the construction timeline but also reduce labor costs as they can be easily repositioned and reused for various configurations. This adaptability makes them particularly appealing for projects that prioritize sustainability.

Additionally, the application of magnetic formwork extends beyond traditional concrete pouring. New design techniques enable the creation of complex shapes and structures that were previously difficult to achieve with conventional methods. As architects and engineers embrace these innovations, the construction industry can expect a surge in creative designs that push the boundaries of architectural possibilities. Moreover, the incorporation of digital technologies allows for real-time adjustments, ensuring that the construction process is both efficient and precise, ultimately leading to higher quality outcomes in building projects.