Choosing the right Magnetic Fixing Solutions For Precast Concrete can be challenging. These solutions play a crucial role in construction projects. They ensure safety, efficiency, and durability.

When exploring options, consider the specific needs of your project. The type of precast concrete elements matters. Your choice of magnetic fixing can impact not just installation, but also long-term performance. Evaluate materials carefully. Are they suitable for your local climate?

Moreover, reflect on the reliability of your suppliers. Not all magnetic systems are equal. Some may not withstand weight loads or environmental stress. This may lead to unexpected failures. Take time to research and ask for expert advice. Quality should never be compromised for cost savings.

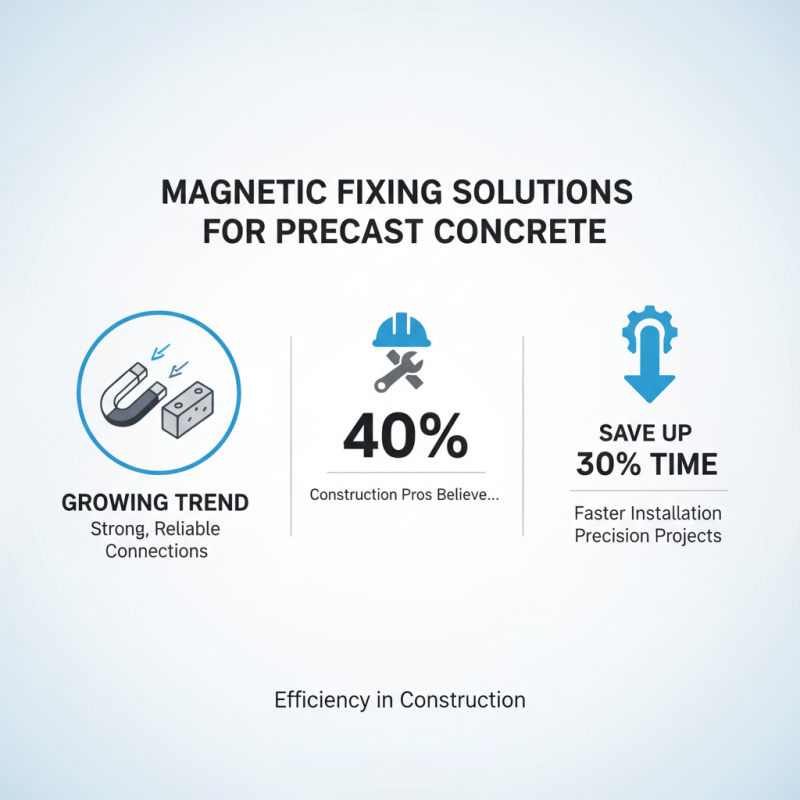

Magnetic fixing solutions for precast concrete are a growing trend in construction. These systems leverage the power of magnets to provide strong, reliable connections for concrete elements. According to a recent industry report, 40% of construction professionals believe that magnetic solutions can reduce installation time by up to 30%. This efficiency is critical in projects where time and precision matter.

Understanding the mechanics behind these solutions is essential. Magnetic fixing systems allow for easy adjustments during the installation process. They ensure that elements align correctly, reducing the risk of costly mistakes. An analysis revealed that nearly 25% of construction errors stem from misalignments during assembly. By utilizing magnetic solutions, contractors could potentially lower these error rates.

However, there are challenges to consider. Not all precast materials respond equally to magnetic systems. Some concrete types may not provide the grip needed for effective holding power. In such cases, reliance on magnets may lead to safety concerns. Moreover, the potential for wear and tear over time should not be overlooked. Regular maintenance becomes essential to ensure long-term effectiveness. Balancing these factors is crucial for successful implementation.

When evaluating magnetic fixing systems for precast concrete, various options exist. Magnetic plates are common. They offer strong attachment and can be repositioned easily. Some systems have adjustable magnets. This flexibility can help when dealing with different concrete thicknesses.

Consider the strength and holding capacity of each type. Larger magnets may provide better support. However, they can also increase costs. It’s important to weigh the budget against the project’s demands. Many users find that lightweight systems are easier to handle. But do they perform adequately under stress?

Installation can also pose challenges. Some magnetic systems require precise alignment. An error here can lead to significant issues later. Furthermore, think about the environment. Outdoor settings may require more robust solutions to resist weather-related wear. Each project has unique needs. Reflect on your choices carefully.

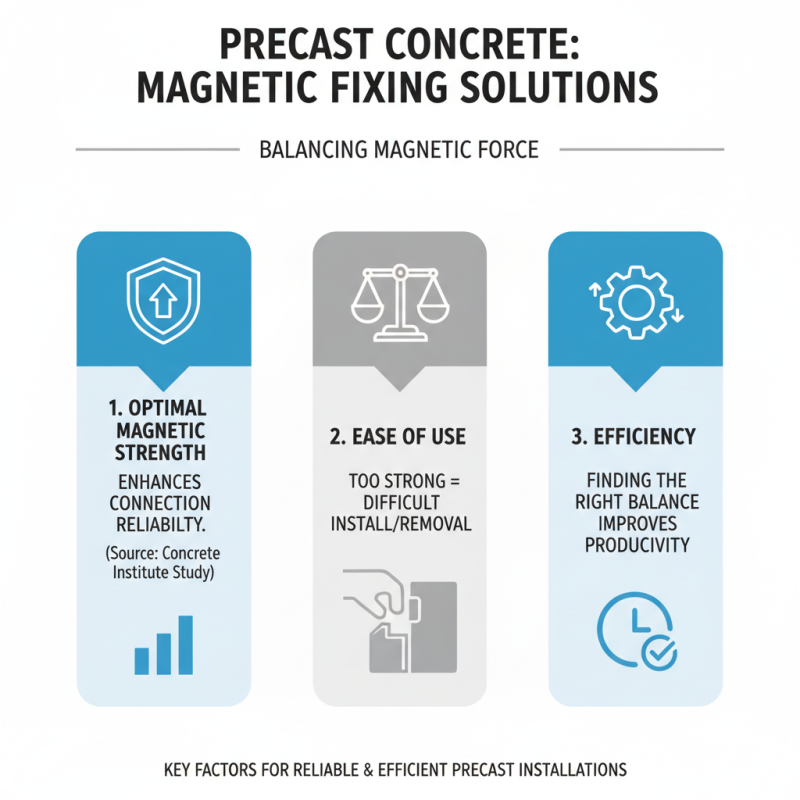

Choosing the right magnetic fixing solutions for precast concrete involves several important factors. One key aspect is magnetic force. A study from the Concrete Institute shows that optimal magnetic strength can enhance connection reliability. Often, users need to balance magnetic force with ease of use. Too strong of a magnet can complicate installation and removal, leading to inefficiencies.

Another crucial factor is the environmental conditions. Precast concrete often faces various weather scenarios. According to an industry report, moisture can affect the performance of magnetic systems. If a solution is not designed to withstand humidity, it may fail. Thus, assessing the site’s climate is essential when selecting a magnetic fixing solution.

Cost considerations cannot be overlooked either. While premium options might seem appealing, budget constraints can shift decisions. Research indicates that about 48% of firms report overspending on inappropriate solutions. It's critical to find a balance between cost and quality. Assessing long-term benefits might also mitigate immediate expenses. Each project presents unique challenges, highlighting the need for careful evaluation.

The installation process of magnetic fixing solutions for precast concrete can be straightforward but requires careful attention. Begin by ensuring the surfaces are clean and free from debris. This preparation is crucial. If not done properly, it can lead to weak adhesion.

Next, position the magnetic fixing devices accurately. Misalignment often occurs if workers rush. Taking the time to double-check placements can prevent issues later. Each component should securely connect to the concrete. Use a level to verify alignment. If any part seems off, adjustments must be made before proceeding.

After installation, inspect each joint. Problems may not be visible at first glance. It can be frustrating if issues arise after everything appears set. Allowing for this reflection time ensures a more durable outcome. Training workers on the nuances of this process can lead to better results. Learning from mistakes is part of the journey.

Maintaining and inspecting magnetic fixing solutions over time is crucial for safety and efficiency. Regular checks help identify wear, corrosion, or loss of magnetism. Use visual inspections to detect any visible damage. Look for signs of dust or debris accumulation. Such build-ups can significantly impact performance.

Periodic testing of the magnetic strength is essential. A simple test can involve checking how securely components are held. If there’s any doubt about usability, it's better to take action. Address issues quickly instead of waiting for a failure. Not all solutions are foolproof, and awareness of limitations is vital.

Environment plays a role too. Factors like humidity and temperature fluctuations can affect performance. It's not uncommon for outdoor installations to require more frequent inspections. Adapting to these conditions ensures longevity. Reflecting on these aspects may lead to more robust approaches in the future.

| Dimension | Value | Notes |

|---|---|---|

| Magnetic Strength | 500 N | Strength suitable for average precast elements |

| Temperature Range | -20°C to 70°C | Suitable for various environmental conditions |

| Material Compatibility | Steel, Concrete | Works well with common construction materials |

| Inspection Frequency | Monthly | Regular checks to ensure functionality |

| Lifespan | 5 years | Expected operational duration under normal conditions |

| Cost per Unit | $15 | Affordable solution for bulk purchasing |