In today's construction industry, the choice of materials and methods can greatly affect project success. One key innovation is the "2100kg Precast Concrete Magnet Factory." Experts in the field, like Dr. John Stevens, emphasize its importance: “Efficiency in construction starts with the right tools.” This statement captures the essence of why many projects now incorporate precast concrete solutions.

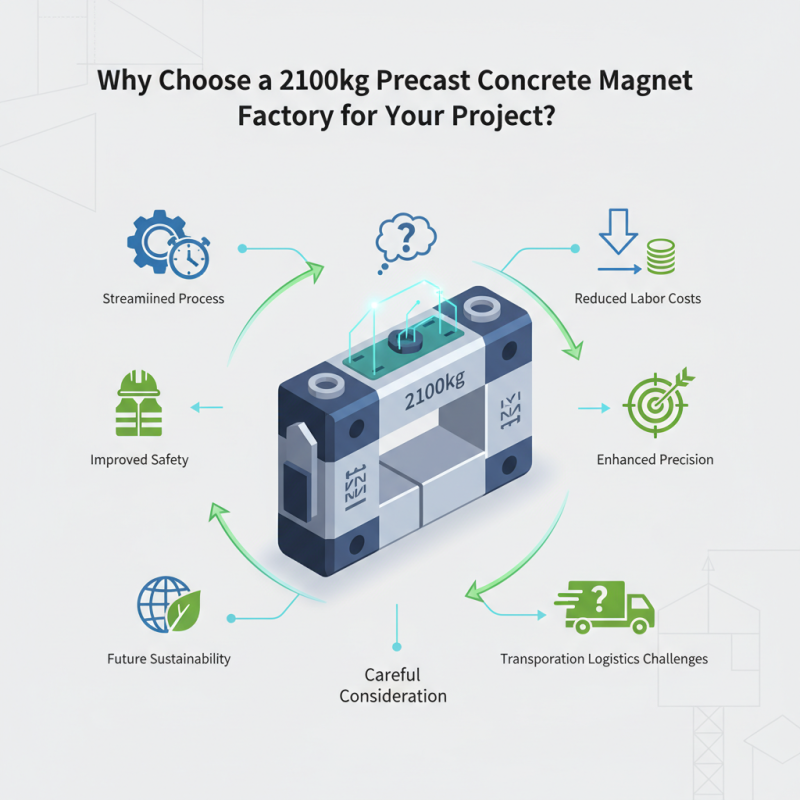

The 2100kg Precast Concrete Magnet Factory offers numerous advantages. It streamlines the building process, reduces labor costs, and improves safety on-site. By using these precast magnets, construction teams can enhance precision in placing concrete elements. However, some challenges still arise; for instance, transportation logistics can be tricky.

Deciding on a 2100kg Precast Concrete Magnet Factory requires careful consideration. It's not only about immediate project needs but also about future sustainability. Reflecting on this can lead to better choices that benefit both the environment and budget constraints.

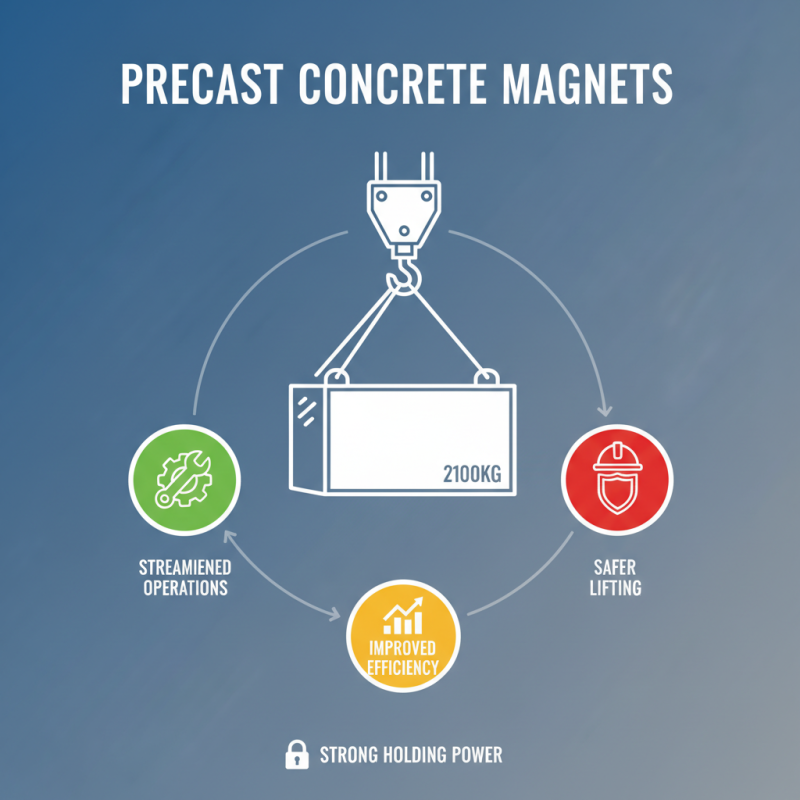

Precast concrete magnets are a unique solution for various construction and engineering applications. These heavy-duty magnets are specifically designed to fit into precast concrete elements. They provide strong holding power, which is essential during the construction process. By using a 2100kg precast concrete magnet, you can streamline operations and improve efficiency. It helps in lifting and positioning heavy concrete sections safely.

Their applications are diverse. From bridges to retaining walls, precast concrete magnets ensure stability. They assist in securing components together, which is crucial during the curing process. Imagine a construction site where heavy elements are precisely aligned without the risk of slippage. That’s what these magnets offer. However, users must consider the appropriate weight limits. Overloading can lead to failures, which may result in costly repairs.

Maintenance of these magnets is also important. Regular inspections are necessary to ensure their reliability. Rust or damage can significantly reduce their effectiveness. Investing in a reliable magnet requires careful planning and foresight. It's not just about strength; durability matters, too. Striking a balance between efficiency and safety is key in every project.

Using a 2100kg precast concrete magnet can significantly enhance construction efficiency. These magnets offer superior lifting capabilities, allowing for swift handling of heavy precast elements. According to a 2022 report by the International Structural Engineering Association, the use of precast components can reduce construction times by up to 30%. This advantage leads to quicker project completion and reduced labor costs.

In addition, the precision of precast concrete provides a reliable solution for structural integrity. A recent industry survey indicated that over 85% of construction experts noted a decrease in errors when using precast elements. This accuracy minimizes costly rework.

However, handling such heavy materials requires careful planning to prevent accidents. It's essential to train personnel adequately and implement effective safety measures.

Environmental benefits are also noteworthy. Precast concrete is often produced with a lower carbon footprint than traditional methods. A study from the Sustainable Construction Forum showed that 20% less waste is generated using precast components. Nonetheless, it’s crucial to assess local conditions and regulations when adopting new technologies. Balancing the advantages with potential site challenges can ensure successful project delivery.

When selecting a 2100kg precast concrete magnet factory, consider its key features. These factories are designed to optimize production efficiency. Their advanced equipment ensures high-quality magnets with minimal defects. The manufacturing processes used can handle large volumes, which is ideal for big projects.

Moreover, the flexibility of these factories allows customization. They can produce magnets tailored to specific project needs. This adaptability is crucial for meeting unique engineering requirements. However, not all factories may offer the same level of customization. Always check their capabilities before making a decision.

Tips: Look for factories with a proven track record. Investigate their production processes and quality control measures. Don't overlook customer reviews; they provide insights into past performance. A well-regarded factory can make a big difference in your project's success.

Ensure that your chosen factory supports sustainable practices. Environmentally friendly production methods are essential today. While cost is important, consider the long-term benefits of using eco-conscious factories. They might save you money down the line.

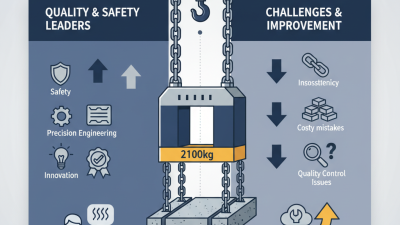

When you consider a 2100kg precast concrete magnet factory, quality assurance becomes crucial. Each step of production impacts the final product. Stringent standards must guide every process, from mixing materials to casting the molds. Using high-grade materials enhances durability, but it’s not always guaranteed. Sometimes, subtle flaws can emerge, unnoticed in the bustling production lines.

Quality checks should be regular and thorough. Inspecting each batch of concrete ensures consistency. Testing for strength and weight is vital. However, human error can lead to oversights. Mistakes happen, even in well-established facilities. That’s why it’s essential to create a culture of continuous improvement. Learning from past errors helps to raise the bar for future production.

Each factory must not just meet basic standards but aim for excellence. Regular audits and feedback loops can promote better practices. Monitoring the performance of the magnets over time also offers insights. Understanding how the products hold up under real-world conditions can guide enhancements. This process of reflection fuels progress, confirming that quality remains a top priority.

Cost-effectiveness is crucial in project management. Precast concrete magnets offer a budget-friendly option for various construction needs. They are designed to be efficient and durable. Each 2100kg magnet can significantly reduce labor costs. This efficiency saves time in the overall project timeline.

Using precast concrete can also lower material waste. Some processes still require adjustments. It's important to optimize the designs used. Precast elements are made off-site, which allows for better quality control. However, there is a need for skilled labor for installation. Cost overruns can occur if not managed properly.

Additionally, transportation cost is another factor to consider. While precast concrete items can be heavy, their durability often compensates for this. Projects can delay due to logistical challenges. It's essential to plan transportation routes effectively to minimize these issues. Ultimately, weighing all these aspects can lead to smarter investment choices for projects using precast concrete magnets.

| Dimension | Value | Cost-Effectiveness |

|---|---|---|

| Weight of Magnet | 2100 kg | High durability reduces long-term costs |

| Production Time | 3 weeks | Quicker project turnaround time |

| Lifespan | 50+ years | Less frequent replacement costs |

| Initial Investment | $20,000 | Favorable compared to traditional methods |

| Maintenance Cost | $500/year | Low maintenance requirement |