The construction industry continually seeks ways to enhance the efficiency and effectiveness of precast concrete production. A critical component in this process is the strategic implementation of "Insert Magnet For Precast." According to a report by the National Precast Concrete Association, optimizing the use of insert magnets can significantly streamline the workflow during the casting process, reducing production time by as much as 20%. This efficiency gain is increasingly vital, as industry demands escalate, and the need for rapid project turnaround becomes paramount.

Moreover, integrating advanced techniques for inserting magnets not only improves operational productivity but also ensures superior end-product quality. Research from the Concrete Research Institute indicates that precision in magnet insertion can lead to fewer defects and rework, saving companies both time and financial resources. By harnessing the best practices for inserting magnets in the precast process, manufacturers can enhance their competitiveness in a market that values both speed and quality. This article delves into the best tips to effectively incorporate insert magnets, helping professionals navigate the complexities of precast production with ease.

In the world of precast concrete, the insertion of magnets is a critical step that significantly enhances the quality and efficiency of production. Understanding the importance of magnet insertion begins with recognizing its role in ensuring precise alignment and positioning of formwork. Magnets allow for rapid setup and adjustments, which is pivotal in a fast-paced manufacturing environment. Their ability to hold panels securely in place not only accelerates the production process but also minimizes the risk of errors that can lead to costly delays or rework.

Moreover, effective magnet insertion contributes to the overall integrity of the precast products. Properly positioned magnets ensure that forms maintain their shape under the pressure of concrete pouring and curing. This not only results in better surface finishes but also strengthens the structural soundness of the precast components. Additionally, understanding the spatial dynamics and weight distribution of magnets aids in optimizing their placement, thereby enhancing stability without compromising accessibility for maintenance or changes during the construction process. By prioritizing effective magnet insertion, manufacturers can streamline their operations while producing high-quality precast concrete elements.

| Tip Number | Tip Description | Benefits | Recommended Tools |

|---|---|---|---|

| 1 | Use high-quality magnets with appropriate strength | Ensures reliable holding capacity during casting | Permanent Magnets |

| 2 | Implement a systematic insertion process | Reduces errors and improves efficiency | Templates for positioning |

| 3 | Train staff on magnet handling | Minimizes risks and enhances productivity | Safety Gear, Instruction Manuals |

| 4 | Regularly inspect magnets for wear and tear | Maintains effectiveness and avoids failures | Inspection Tools |

| 5 | Utilize a magnet release tool | Enhances safety during magnet removal | Magnet Release Tool |

When it comes to efficiently inserting magnets into precast products, having the right tools and equipment is essential. Firstly, you will need a specialized magnet insertion tool designed for this purpose. These tools not only allow for precision placement of the magnets but they also streamline the workflow, drawing on mechanisms that can hold the magnet in place while the concrete sets. Additionally, a clean work surface and proper measuring devices, such as calipers or tape measures, can ensure exact alignment and penetration depth for consistency across all pieces.

In addition to the insertion tools, a good set of personal protective equipment (PPE) should not be overlooked. Safety goggles will protect your eyes from dust or debris that may fly during the insertion process, while gloves can protect your hands from sharp materials or hazardous substances. Moreover, using a pneumatic sander or grinder can help prepare the magnet slots in precast units, ensuring that surfaces are smooth and can accommodate the magnets securely. By equipping yourself with these essential tools and safety measures, you set the stage for a more efficient and effective magnet insertion process.

Inserting magnets into precast elements is a critical step that enhances the structural integrity and efficiency of construction projects. The process begins with selecting the appropriate magnet size and type based on the specific application within precast components, whether for lifting, connecting, or reinforcing. According to the Precast Concrete Institute, utilizing the right magnets not only improves load-bearing capacities but also facilitates quicker assembly on site, reducing overall project timelines by up to 30%.

The step-by-step process begins with careful planning and layout considerations, ensuring that the placement of magnets aligns with other structural elements. Precise measurements are essential to avoid misplacements, which can lead to costly reworks. Next, the magnets should be securely embedded in the precast concrete forms before the concrete curing process begins. Recent studies indicate that incorporating magnets during the casting phase increases the bond strength between the magnet and concrete, leading to a 20% improvement in pull-out resistance compared to retrofitting methods. Once the precast elements are cured, finishing techniques should be applied to ensure that the magnet surfaces are clean and free of any debris, ultimately optimizing their performance when deployed in the field.

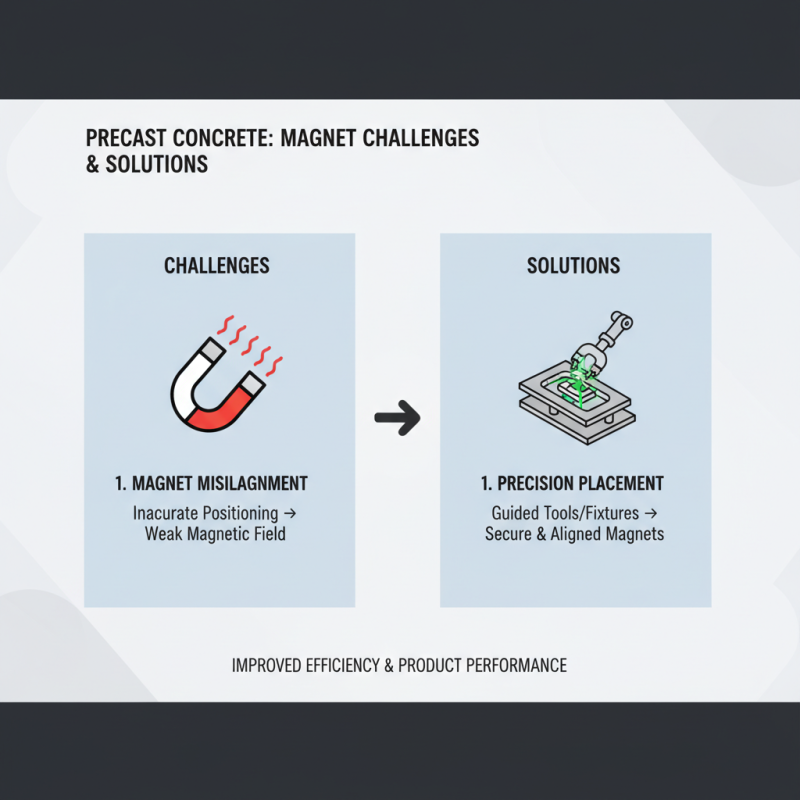

During the process of inserting magnets into precast concrete elements, several common challenges can arise, which can hinder efficiency and effectiveness. One significant issue is misalignment of the magnets, often resulting from inaccurate positioning during setup. This can lead to difficulty in achieving the intended magnetic field strength, impacting the performance of the finished product. A practical solution to this challenge includes utilizing precision placement tools or fixtures that can help guide the magnets into the correct position, ensuring that they are secure and correctly aligned before the curing process begins.

Another challenge frequently encountered is the durability of the adhesive used to secure the magnets. Environmental conditions, changes in temperature, and moisture levels can influence how well the adhesive holds over time. To combat this, selecting a high-quality adhesive specifically designed for heavy-duty applications can significantly enhance the longevity and reliability of the magnet insertion. Additionally, implementing a curing process that accommodates these environmental factors can further ensure the integrity of the magnets once installed. By addressing these challenges proactively, manufacturers can streamline their workflows and improve the overall quality of precast products.

When it comes to ensuring effective magnet placement and alignment for precast components, precision and planning are paramount. First, it's crucial to understand the specific requirements of the precast element being produced. Detailed project specifications should guide the placement of magnets, taking into account factors such as load distribution and structural integrity. A well-structured layout plan can prevent common alignment issues that may arise during the casting process.

Moreover, the use of jigs and guides can significantly enhance the accuracy of magnet placement. By designing and implementing fixtures that hold the magnets in place during setup, workers can maintain consistent positioning across multiple casts. It's also advisable to regularly check the alignment before pouring concrete, as even minor shifts can lead to substantial discrepancies in the final product. Coordinating inspections with team members during setup can foster a collaborative environment to ensure that every step is executed systematically, promoting efficiency and reducing errors.