Shuttering magnets are essential tools in precast production. These devices securely hold formwork in place, ensuring precise concrete placement. Their effectiveness can greatly influence the quality of precast elements.

Choosing the best shuttering magnets for precast production is not straightforward. Various factors come into play: magnet strength, size, and design. A weak magnet might not hold heavy forms, while an oversized magnet could be cumbersome. All aspects require careful consideration.

Some magnets perform admirably, but they may fall short in specific situations. It's crucial to assess performance based on the application. Understanding these nuances can lead to better decisions in precast production. Investing time in researching options is worthwhile for successful outcomes.

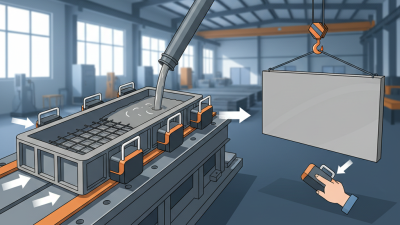

Shuttering magnets play a crucial role in precast production. They provide essential support for formwork systems in various construction applications. These magnets help ensure the precise alignment and stability of concrete molds during the curing process. A recent industry report indicated that the use of shuttering magnets can significantly reduce labor costs by up to 30%. This efficiency makes them a favored choice in modern construction.

Understanding how these magnets operate is vital. They often feature strong magnetic forces, capable of holding heavy panels securely in place. Many magnets can accommodate different thicknesses, ensuring versatility. However, improper placement or insufficient magnetic strength can lead to significant errors, impacting the quality of the finished product. An analysis showed that production delays due to misaligned forms can increase overall costs by nearly 15%.

In the fast-paced world of precast concrete, choosing the right magnets matters. Even small discrepancies during the setup can result in costly defects. As more companies adopt automated systems, the demand for high-quality shuttering magnets will likely rise. Continuous improvement and adaptation are necessary to keep up with evolving technological advancements and industry needs.

| Type of Magnet | Holding Force (kg) | Material Compatibility | Application | Advantages |

|---|---|---|---|---|

| Permanent Shuttering Magnet | 1200 | Steel, Concrete | Panel Formwork | High durability, Cost-effective |

| Electromagnetic Shuttering Magnet | 1500 | Steel | Complex Shapes | Quick setup, Adjustable force |

| Reversible Shuttering Magnet | 1000 | Steel, Aluminum | Double Sided Forms | Versatility, Space-saving |

| Vacuum Shuttering Magnet | 1100 | Smooth Surfaces | Flat Panels | Precision hold, Clean application |

When choosing shuttering magnets for precast production, key features should be carefully considered. Effective magnets must provide strong holding power to ensure stability during the casting process. Industry reports indicate that magnet efficiency can influence production timelines by up to 30%. A reliable magnet will reduce movement, leading to fewer defects in the finished product.

Portability is another crucial aspect. Many projects require quick setups and repositioning. Lightweight magnets make this easier, allowing teams to adapt swiftly. Additionally, their durability is vital. A study found that magnets that last longer can reduce overall costs by nearly 20%. It’s important to assess the magnetic strength and the materials used. Some less expensive options may fail under pressure.

Another area to consider is ease of use. Complex installation can slow down operations. Simplified designs promote faster setup and fewer errors. However, some manufacturers overlook this, causing frustration on-site. The right balance of functionality and user-friendliness is essential. Finding an optimal solution is often challenging but crucial for efficient precast production.

Shuttering magnets play a crucial role in precast production. They secure formwork in place, ensuring precise concrete casting. These magnets come in various types, each serving distinct functions.

The most common types are block magnets and circular magnets. Block magnets are used for standard applications. They provide strong holding power, often rated up to 1200 kg. Circular magnets, on the other hand, are versatile and ideal for curved surfaces. Their compact size allows for easy handling.

Data from industry reports indicate that the demand for shuttering magnets is on the rise. Over the last five years, usage worldwide has increased by 15%. However, many manufacturers struggle with quality control. Inconsistent pulling forces can lead to errors in precast elements. Further research is needed to address these issues and improve overall product reliability.

Shuttering magnets play a crucial role in precast concrete production. They create a reliable formwork solution that enhances efficiency. By holding molds in place, these magnets significantly reduce setup time. Workers benefit from quicker adjustments and alignment. The ease of use encourages a smoother workflow.

Using shuttering magnets also improves safety on the job site. Their strong grip minimizes the risk of accidents caused by shifting molds. However, not all magnets perform equally. Some may lose strength over time or fail during critical moments. This highlights the importance of regular maintenance and checks.

Another advantage is the cost-effectiveness of these tools. They can lower labor costs by requiring fewer workers for setup. Yet, reliance on low-quality magnets could lead to costly delays or defects. It's essential to balance price with reliability. Users must reflect on their choices carefully to ensure they are making sound investments.

In precast production, shuttering magnets play a vital role. They hold forms securely in place during the pouring of concrete. Choosing the right product can streamline the process and improve efficiency. The best options often feature adjustable holding forces and quick-release functions. These features allow for easy repositioning and removal.

Many manufacturers offer innovative designs that enhance safety and reduce setup time. Some products include integrated handles for better maneuverability. However, not all magnets perform equally in various weather conditions. A magnet that works well indoors may struggle outdoors. It's essential to assess specific project needs before making a selection.

Cost is another crucial factor. Some cheaper options may compromise quality. Investing in high-quality magnets can save time and reduce errors. Yet, there are also budget-friendly choices that perform adequately for smaller projects. Finding the balance between cost and performance can be challenging. Every project has unique demands, which makes careful evaluation necessary.