In the realm of concrete construction, the efficiency and effectiveness of formwork systems are pivotal to the end results, particularly with the increasing demand for durable and high-quality structures. A crucial element that has gained traction in recent years is the "Shuttering Magnet For Concrete Formwork." According to a recent industry report published by the Global Concrete Formwork Market, the market for innovative formwork solutions is projected to reach $XX billion by 2025, indicating a significant shift towards more advanced technologies that enhance productivity and reduce labor costs.

Expert in the field, Dr. Michael Johnson, an acclaimed civil engineer specializing in formwork technologies, emphasizes the importance of adaptability in this sector. He states, "The introduction of high-quality shuttering magnets has revolutionized the way we approach concrete formwork, allowing for easier assembly and disassembly while ensuring precision in concrete placement." As construction projects become more complex, the demand for efficient and reliable formwork solutions continues to grow, pushing the boundaries of what can be achieved with traditional methods.

Incorporating these innovative shuttering magnets not only streamlines the construction process but also significantly reduces material waste and labor hours, contributing to a more sustainable building practice. As contractors and builders seek to overcome challenges such as project timelines and budget constraints, the adoption of efficient tools like the "Shuttering Magnet For Concrete Formwork" becomes increasingly vital in achieving optimal performance and high-quality results in concrete construction.

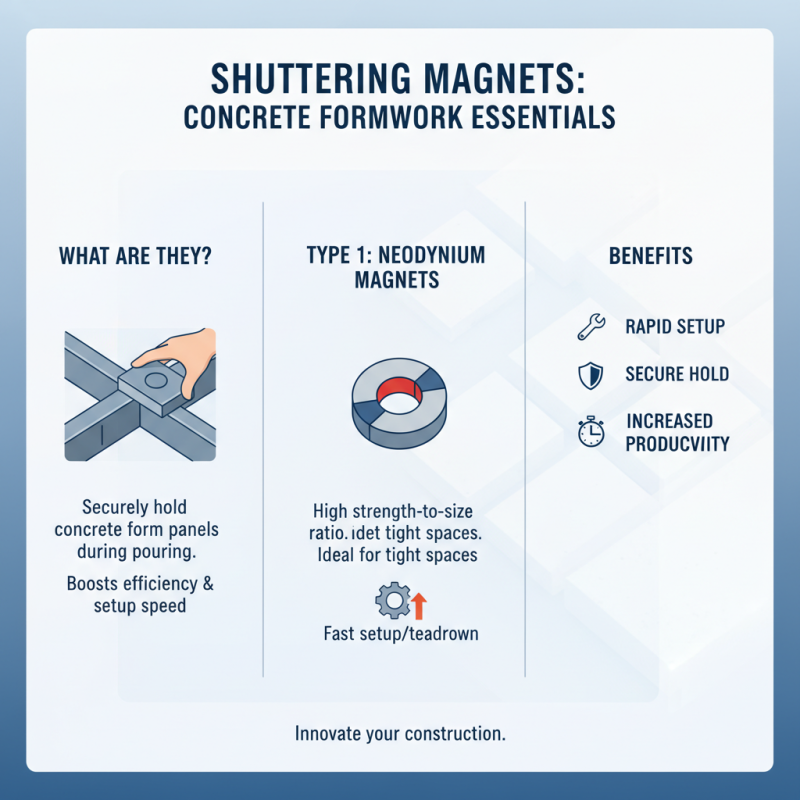

Shuttering magnets play a pivotal role in the construction process, particularly in the realm of concrete formwork. These innovative devices securely hold the formwork panels in place, ensuring precise alignment and stability during the pouring and curing of concrete. By utilizing shuttering magnets, builders can streamline their operations, reducing the risk of errors and material waste. The ease of installation and removal makes these magnets an essential tool, especially in projects requiring frequent adjustments or temporary setups.

When working with shuttering magnets, it is essential to understand their placement and the weight capacity they can handle. Proper positioning not only enhances the effectiveness of the magnets but also optimizes the overall project efficiency. Tips for maximizing the benefits include ensuring a clean, smooth surface for the magnets to adhere to, and regularly checking their strength throughout the construction process. Regular maintenance and inspection of magnets can help prevent accidents and ensure longevity.

In addition to their functional advantages, shuttering magnets contribute to a safer work environment. Their robust design minimizes the risk of formwork displacement, which can lead to costly delays and safety hazards. For best practices, always consider the specific requirements of your formwork design, such as height and exposure to elements, to ensure the correct type and number of magnets are used for optimal results.

Shuttering magnets are essential tools in concrete formwork, designed to securely hold form panels in place during the pouring of concrete. There are a few primary types of shuttering magnets, each with specific features and applications suited to different project requirements. For instance, neodymium magnets are known for their high strength-to-size ratio, making them ideal for projects where space is limited but strong holding power is necessary. These magnets allow for rapid setup and teardown of formwork, which enhances overall productivity on construction sites.

Another type is the standard flat magnet, which often includes adjustable plates for versatile positioning. This feature is particularly beneficial in complex formwork configurations, allowing for tailored solutions that accommodate varying panel dimensions and shapes. Additionally, some shuttering magnets come with integrated safety locks, which provide an extra layer of security against accidental dislodgement during concrete pouring. Their robust design and ease of use make them suitable for various applications, from residential builds to large commercial projects, ensuring that construction teams can achieve precise and reliable concrete finishes.

Shuttering magnets have gained significant popularity in the construction industry due to their ability to streamline the concrete formwork process. One of the primary advantages of using shuttering magnets is their efficiency in securing formwork elements. Unlike traditional methods that often rely on cumbersome clamping systems, these magnets provide a quick and reliable means of attachment. This efficiency not only accelerates the installation process but also reduces labor costs, enabling contractors to focus resources on other critical aspects of the project.

Another key benefit of shuttering magnets is their versatility. They can be used effectively on various surface types and in different weather conditions, assuring a strong hold during the pouring and curing of concrete. This adaptability makes them an ideal choice for a wide range of construction projects, from residential buildings to large commercial complexes. Moreover, the reduced risk of shift or movement during casting enhances the overall quality and precision of the concrete structure, preventing costly errors and rework often associated with misaligned formwork.

When selecting the best shuttering magnet for concrete formwork, understanding your specific needs is essential. The ideal magnet should match the size and weight of your formwork while ensuring a secure hold during the pouring process. Consider the type of concrete being used, as different mixes may exert varying levels of pressure on the formwork. Choose a magnet that can withstand these conditions without compromising its fastening capability.

Tips for choosing the right shuttering magnet include evaluating the strength and size of the magnet in relation to your formwork design. It’s also crucial to check the magnet’s durability, particularly in harsh construction environments. A robust and reliable magnet can enhance workflow efficiency and reduce the risk of operational delays due to formwork failures. Additionally, consider the ease of installation and removal, as this can save time and effort on the job site.

Another key aspect is the magnetic pull force. A stronger magnet may be necessary for larger, heavier formwork systems or for situations where the concrete pressure is expected to be high. Ensuring that the pull force is adequate not only secures the formwork but also contributes to a smooth finish on the poured concrete, reducing the likelihood of defects. Always conduct a thorough assessment of your project requirements before making a choice to ensure safety and effectiveness in your concrete pouring operations.

To ensure the longevity of shuttering magnets used in concrete formwork, proper maintenance practices are crucial. Regular inspections should be conducted to identify any wear and tear. According to a report by the International Journal of Construction Research and Innovation, maintaining equipment can reduce replacement costs by up to 25%. This means that by proactively checking for issues such as rust, corrosion, or mechanical failures, contractors can extend the lifespan of their shuttering magnets significantly.

Additionally, cleaning the magnets after each use is essential. Concrete residues can accumulate and affect the magnetic strength, making it less effective in holding formwork securely. A study from the Construction Industry Institute indicated that contaminants can reduce the holding capacity of magnets by even 30% if not addressed. It is recommended to use mild detergents and a soft brush to remove any leftover concrete, ensuring optimal performance for future projects. Regular lubrication of movable parts can also improve functionality and prevent malfunction, adding to the overall effectiveness and reliability of the shuttering magnets.

This chart compares the strength of different shuttering magnets used in concrete formwork. The data indicates that Magnet B has the highest strength at 450 N, while Magnet C has the lowest strength at 150 N. Understanding these strengths can help in selecting the right shuttering magnet for specific construction needs.