In construction projects, efficiency and reliability are key. The "Shuttering Magnet Adapter" is a vital tool for modern builders. This adapter allows secure panel placement, ensuring accurate alignment. It simplifies the process of forming and pouring concrete, saving time and effort.

Choosing the right adapter can be challenging. Many options flood the market, each claiming superiority. However, not all adapters are built to last. Some fail under heavy use, leading to costly repairs. Evaluating quality and performance is essential for successful projects.

Consider factors such as strength and adjustability. The best adapters offer versatile solutions for various surfaces. In some cases, the price reflects quality, but that’s not always true. Research and real user reviews can guide better choices in 2026.

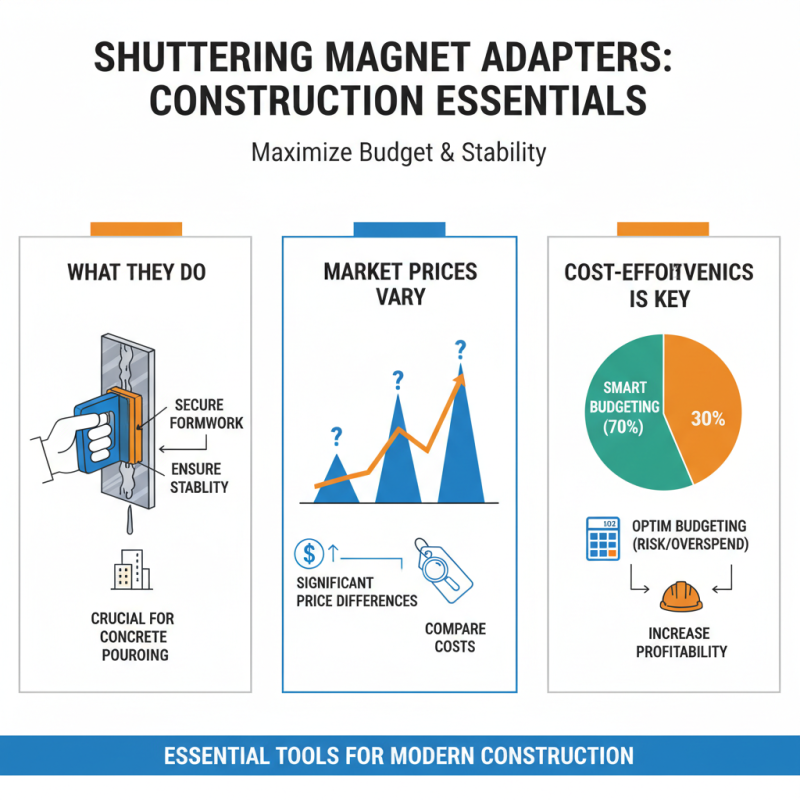

Shuttering magnet adapters play a crucial role in construction projects. These devices help secure formwork on various surfaces. They provide stability during concrete pouring and ensure accurate shapes. In many cases, however, contractors face challenges with alignment. A slight misplacement can lead to leaks or weak spots in the final structure.

Understanding the materials used for shuttering magnet adapters can prevent common issues. High-quality magnets yield strong holding power, while lower-quality options might weaken over time. Ensuring that magnets are properly cleaned and free from debris is essential. This simple step can significantly improve performance. In some projects, overlooking maintenance led to frustrating delays.

Construction professionals must evaluate their needs carefully. Not every project requires heavy-duty magnets, but general guidelines can help. Adaptability is also vital; some sites demand specific sizes or strengths. Continuous evaluation and open-mindedness can lead to better outcomes. Recognizing that not all purchases or deployments will be perfect encourages learning and growth in the field.

When selecting a shuttering magnet adapter, several key features stand out. First, the holding capacity is crucial. According to industry reports, an adapter should hold at least 1500 Newtons to ensure stability during concrete pouring. This factor directly influences safety on the construction site. A weak hold can lead to shifting forms, resulting in costly mistakes.

Next, durability cannot be overlooked. Adapters made from high-quality materials can withstand harsh conditions. Reports show that steel components show less wear and tear over time. This is vital for frequent reuse. Additionally, ease of installation plays a significant role in project timelines. Magnetic connectors should be user-friendly. Complicated setups can lead to delays and frustration, particularly in large projects.

Lastly, the weight of the adapters is important. Lighter options can ease maneuverability without sacrificing strength. Yet, balancing weight and performance is often a challenge. A common issue is that some adapters may not meet the required holding capacity while remaining lightweight. Reports indicate this is an area that needs ongoing improvement. Striking this balance can reduce labor costs and improve overall project efficiency.

This chart compares the performance of three categories of shuttering magnet adapters based on key features such as magnet strength, ease of use, durability, cost, and weight. The data highlights the advantages and disadvantages of each category, aiding in the selection of the best product for construction projects.

In 2026, the construction industry emphasizes efficient tools. Shuttering magnet adapters are crucial for formwork solutions. They secure panels in place effectively, ensuring stability. Choosing the right model can boost project efficiency and safety.

Top brands focus on durability and magnet strength. Some models feature quick-release mechanisms, saving time during assembly. Users appreciate the ease of adjustment, especially in tight spaces. However, not all models perform equally. Some may lack the necessary holding power under specific conditions, leading to potential issues on-site.

It’s important to review user experiences. Inconsistent feedback on magnet strength can influence choices. Some workers may find certain models cumbersome to handle. Considering the environment and application is vital. Factors like temperature and formwork weight can affect magnet efficiency.

Shuttering magnet adapters have become essential in construction projects. These tools are crucial for securing formwork and ensuring stability during concrete pouring. However, prices can vary significantly across the market. Understanding the cost-effectiveness of different adapters is vital for contractors aiming to maximize their budgets.

When evaluating the prices of shuttering magnet adapters, it's important to consider both quality and durability. Some cheaper options might seem appealing but could compromise safety and reliability. For instance, weaker magnets may not hold as securely, leading to costly mistakes. On the other hand, premium adapters often come with warranties, providing peace of mind.

Not every project requires the highest-end product. Sometimes, mid-range options strike the best balance between cost and performance. Assessing project needs can help choose the right adapter. Will it be used for multiple projects or just one? Smaller projects might not justify higher costs, while larger ones might benefit from invests in durable solutions. Reflecting on these aspects can guide contractors in making smarter choices.

Shuttering magnet adapters play a vital role in modern construction projects. These devices secure formwork, allowing for precise and efficient concrete placement. Research indicates that using these adapters can improve placement accuracy by up to 30%. This increase is significant for projects requiring stringent specifications.

When using shuttering magnet adapters, efficiency is key. Proper lining up of the adapters can save time during setup. Taking the time to align them may seem tedious, but it reduces the risk of errors later. Additionally, on-site workers should frequently check the securing strength of the magnets. Studies show that construction errors often arise from insufficient checks. This can lead to safety hazards, delays, and increased costs.

It's important to remember that while these tools are effective, they are not infallible. Improper use can lead to formwork failures. Training workers on the correct installation method can mitigate this risk. Regular reviews of their performance on-site should be conducted. Observing and learning from mistakes can enhance both individual and team efficiencies. Ultimately, integrating best practices for using shuttering magnet adapters can transform project outcomes positively.