The precast concrete industry has increasingly turned to innovative solutions to improve production efficiency and reduce costs. Among these advancements, the use of shuttering magnets for precast production stands out as a game changer. According to industry reports, the adoption of shuttering magnets can enhance production speed by up to 30%, significantly reducing the time required for setting forms and ensuring precise alignment. These magnets allow for easy adjustments and repositioning, which not only streamlines the workflow but also minimizes material waste. Furthermore, a recent study indicated that 70% of precast manufacturers have seen a notable improvement in quality control due to the enhanced stability and reliability offered by shuttering magnets. As the demand for high-quality precast components continues to rise, understanding the benefits of shuttering magnets for precast production becomes crucial for companies aiming to stay competitive in this rapidly evolving market.

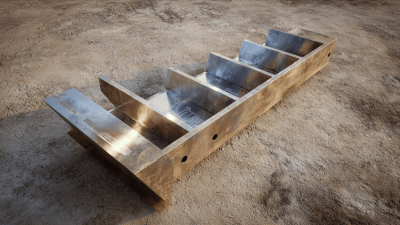

Shuttering magnets have become an essential tool in enhancing the efficiency of precast concrete production processes. These innovative devices provide a streamlined approach to formwork, allowing for quicker setup times and reducing labor costs. By utilizing shuttering magnets, manufacturers can easily position and secure form panels without the need for traditional clamping methods, which can be both time-consuming and labor-intensive. This streamlining not only accelerates production but also increases accuracy in the final product, ensuring a higher standard of quality in each concrete piece.

Tip: When implementing shuttering magnets, it's crucial to ensure they are compatible with your existing formwork systems. Regularly check the magnets' strength and condition to maintain optimal performance and prevent any production delays.

The advantages of using shuttering magnets extend beyond simple time savings. They also allow for greater flexibility in design, enabling producers to create complex shapes and designs that were previously challenging with conventional methods. This adaptability can lead to an expanded portfolio of precast offerings, catering to diverse market needs and customer preferences.

Tip: Consider investing in variable sizes of shuttering magnets to accommodate a range of forms and designs, maximizing your production capabilities while minimizing setup challenges.

Shuttering magnets are revolutionizing the precast production industry by offering significant cost reductions that enhance manufacturing efficiency. According to recent reports from the Precast/Prestressed Concrete Institute (PCI), the adoption of shuttering magnets can reduce labor costs by up to 30%. This is largely due to the elimination of traditional clamping methods, which require additional workforce and time to setup and dismantle. By streamlining the formwork process, shuttering magnets allow for quicker turnarounds between pours, effectively increasing production capacity.

Shuttering magnets are revolutionizing the precast production industry by offering significant cost reductions that enhance manufacturing efficiency. According to recent reports from the Precast/Prestressed Concrete Institute (PCI), the adoption of shuttering magnets can reduce labor costs by up to 30%. This is largely due to the elimination of traditional clamping methods, which require additional workforce and time to setup and dismantle. By streamlining the formwork process, shuttering magnets allow for quicker turnarounds between pours, effectively increasing production capacity.

Additionally, a study conducted by the Concrete Industry Management (CIM) program found that utilizing shuttering magnets can lead to material savings of approximately 15%. The precise alignment and adjustment capabilities of these magnets minimize material waste and ensure optimal use of concrete resources. This not only lowers the overall production costs but also contributes to sustainable practices within the industry. As precast manufacturers continue to face pressure to improve their bottom line while maintaining quality, the integration of shuttering magnets stands out as a cost-effective solution that enhances both productivity and profitability.

Shuttering magnets are transforming labor efficiency in precast production facilities by offering a variety of benefits that streamline operations. According to industry reports, the integration of shuttering magnets into precast concrete processes can reduce assembly time by up to 50%. This significant time savings translates into lower labor costs and increased output, allowing facilities to meet growing demands more effectively. The magnets facilitate quicker form setup and adjustments, minimizing delays often caused by traditional clamping methods.

Moreover, recent studies highlight the trend of automation in the construction industry, with robots being employed to optimize concrete prefabrication. In combination with reusable shuttering systems, this automation not only enhances production efficiency but also promotes sustainability by reducing material waste. Facilities that adopt this innovative approach can see productivity boosts of approximately 30%, leading to a more sustainable operation overall.

Tips: To maximize the effectiveness of shuttering magnets, ensure that workers are properly trained in their use, which can significantly reduce setup errors. Additionally, consider investing in a modular shuttering system that allows for easy adjustment and maintenance, further increasing labor efficiency in your precast production.

Shuttering magnets have revolutionized the precast concrete industry by enhancing quality control in the production of concrete elements. These magnets provide a reliable and efficient way to secure formwork, ensuring precise alignment and stability during the pouring process. According to a report by the National Ready Mixed Concrete Association, the use of advanced formwork systems, including shuttering magnets, can lead to a 15-20% reduction in defects associated with misalignment and formwork failures. This allows manufacturers to produce higher quality products consistently.

One significant advantage of shuttering magnets is their ability to streamline the quality assurance process. By offering quick and easy adjustments during setup, these tools minimize human error and enhance the overall accuracy of the mold configuration. This is crucial, as the American Concrete Institute emphasizes that even minor discrepancies in formwork can lead to major structural failures down the line. Implementing shuttering magnets can help maintain rigorous standards essential for compliance with industry regulations.

Tips for Implementation:

Shuttering magnets have emerged as a pivotal innovation in sustainable construction practices, particularly in precast production. By offering a reliable and efficient means of forming concrete structures, these magnets minimize the environmental footprint associated with conventional shuttering methods. Their reusable nature significantly reduces the need for single-use materials, which not only conserves resources but also diminishes construction waste, aligning with the growing emphasis on sustainability in the building sector.

In tandem with other advancements, such as Geopolymer 3D printing, the integration of shuttering magnets can contribute to a more eco-friendly construction paradigm. The exploration of alternative materials, like mine tailings, further enhances the potential for sustainable practices. These developments indicate a shift towards innovative methods that prioritize environmental health and resource efficiency, ultimately leading to structures that are not only robust but also aligned with the principles of sustainable development. The combined effect of these technologies could revolutionize precast production, making it a cornerstone of modern eco-conscious construction.