In the construction industry, efficiency and precision are essential. The "Magnetic Shuttering System For Prestressed" offers innovative solutions. This system uses magnets for quick and secure formwork. It improves the placement of concrete, reducing labor costs.

One main advantage is the reduction in setup time. Traditional methods require extensive manual work. However, the magnetic system streamlines this process. It enhances flexibility in designs, allowing for various shapes and sizes. This adaptability can lead to better project outcomes.

Despite its benefits, there are challenges to consider. Not all projects may require a magnetic system. It's crucial to assess when it is most effective. Overall, the Magnetic Shuttering System offers notable improvements. Yet, careful evaluation of its application is necessary.

Magnetic shuttering systems have transformed the approach to prestressed concrete applications. Their ease of assembly streamlines construction processes. Workers can quickly set up the forms without extensive labor. This efficiency allows for faster project timelines. Many contractors appreciate this speed in busy construction environments.

Another key benefit is the adaptability of these systems. Magnetic shuttering can easily adjust to different shapes and sizes. This flexibility is crucial for unique architectural designs. However, not all designers fully utilize this potential. Some may stick to traditional shapes, limiting innovative possibilities.

Moreover, the reusability of magnetic shuttering systems reduces waste. This makes them an eco-friendlier option compared to conventional materials. Yet, there may be concerns about the initial investment costs. Some projects might hesitate to shift from traditional methods. But those who embrace magnetic systems often find the long-term savings worthwhile. Their versatility and sustainability create a balance that benefits modern construction.

| Benefit | Description | Impact on Project |

|---|---|---|

| Enhanced Speed of Installation | Magnetic shuttering systems allow for quick setup and dismantling, reducing labor costs and project timelines. | Accelerates project completion, enhancing productivity. |

| Increased Versatility | Magnetic shutters can be used for various shapes and sizes of concrete elements, providing flexibility in design. | Facilitates innovative structural designs without added complexities. |

| Cost Efficiency | Reduces material waste and lowers overall project costs due to reusable components. | Improved budget management and resource allocation for projects. |

| Improved Surface Finish | Magnetic shutters provide a smooth surface finish that requires minimal additional work, enhancing aesthetic quality. | Reduces finishing time and costs, ensuring high-quality output. |

| Safety Enhancements | Magnetic systems can be operated easily from a distance, reducing risks associated with manual labor at heights. | Enhances worker safety, potentially lowering insurance costs and liability. |

The magnetic shuttering system revolutionizes construction speed. Studies show that construction projects using this technology can accelerate timelines by up to 30%. This efficiency is achieved through the rapid setup and flexibility of magnetic panels. They adhere securely to forms, reducing the time needed for assembly and adjustments.

Concrete elements can be cast in place without waiting for labor-intensive alignments. This system allows workers to focus on other tasks while panels are magnetically secured. The reduction in required manpower is notable; a construction site can see labor costs decline by 15%. However, reliance on this technology can raise questions. Are workers being adequately trained to adapt to new methods?

Some contractors report challenges in sourcing compatible materials. The need for specific configurations can delay projects unexpectedly. While the speed benefits are substantial, planning must account for potential supply chain issues. Ultimately, leveraging magnetic shuttering technology can boost productivity, yet it requires careful management of resources and training.

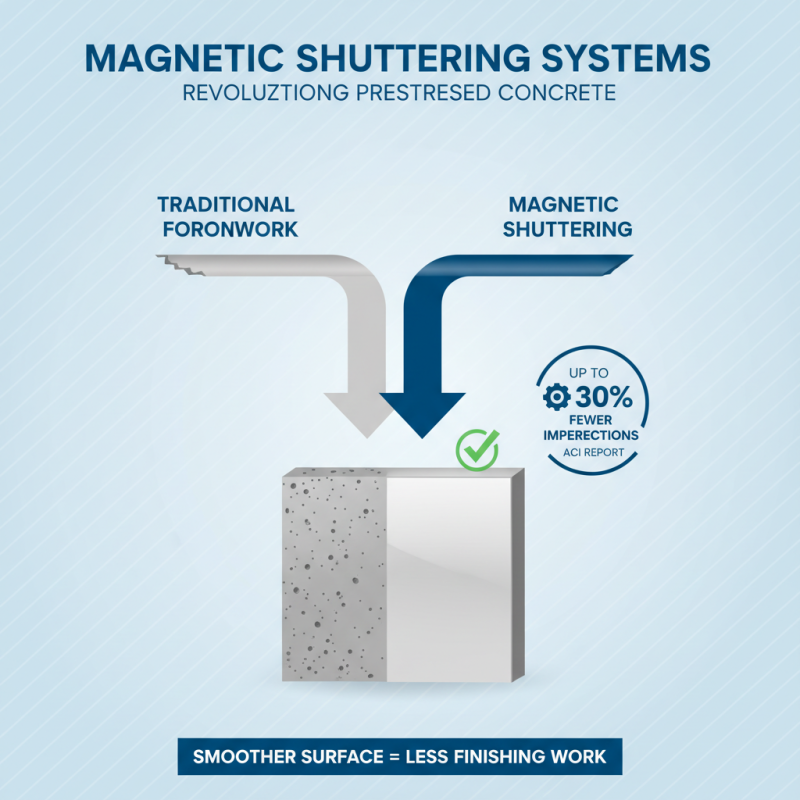

Magnetic shuttering systems are changing the way prestressed concrete is created. One of the standout benefits is the improvement in concrete surface finish quality. A report from the American Concrete Institute highlights that effective formwork can reduce surface imperfections by up to 30%. This is a significant advantage for any construction project, as a smooth surface minimizes additional finishing work.

Concrete pours with magnetic shuttering result in fewer gaps and irregularities. The magnetic attraction holds the panels tightly together, preventing any leakage of concrete. Workers benefit from a more uniform and aesthetic surface finish. This can lead to reduced costs associated with post-pour treatments. It's essential to design the project considering this efficiency right from the start.

**Tip:** Always test the magnetic system in a controlled environment before full-scale application. The interaction between concrete and shuttering should be evaluated.

In addition, while magnetic shuttering offers benefits, it’s vital to recognize potential limitations. The setup requires precise alignment and care during installation. Even a minor misalignment can lead to flaws in the final product. Regular training for the crew is necessary to avoid such pitfalls. Proper handling ensures the quality remains high throughout the project.

The cost efficiency of magnetic shuttering systems compared to traditional systems is truly remarkable. Reports indicate that these systems can reduce installation costs by up to 30%. This is mainly due to the speed of installation. Magnetic shutters can be set up in a fraction of the time it takes for conventional methods. Faster installation means labor costs are significantly lower.

Moreover, the longevity of magnetic shuttering contributes to its cost-effectiveness. Traditional systems often require frequent maintenance. In contrast, magnetic options have a much lower failure rate. Data suggests that magnetic systems can last twice as long as some conventional alternatives. This durability results in fewer replacements over time.

However, it's essential to acknowledge that not all projects benefit equally from these systems. Some sites may face challenges when integrating magnetic solutions. Factors like environment and structure complexity can influence efficiency. Understanding these variables is crucial for the best outcomes. In many cases, proper planning and adaptation can help mitigate potential drawbacks.

Magnetic shuttering systems are transforming the construction of prestressed structures with their sustainable benefits. The primary advantage lies in their reusability. Unlike traditional forms, magnetic shuttering can be used multiple times, reducing waste significantly. This aspect alone minimizes the environmental footprint of construction projects. Additionally, the lightweight nature of these systems allows for easier transportation and handling on-site.

One notable sustainability impact is the reduction in materials used. By optimizing the formwork design, less concrete is wasted. This leads to cost savings and a lighter load on resources. Onsite assembly becomes quicker and requires less energy. The quicker setup reduces labor time and contributes to lower emissions.

Tip: Always consider the lifecycle of materials in your projects. Ask how often they can be reused or recycled.

Despite the advantages, proper planning is vital. Magnetic shuttering requires skilled workers familiar with the technology. If not handled correctly, it might lead to complications during the concrete setting process.

Tip: Invest time in training staff. Understanding the nuances will harness the full potential of magnetic systems.