In the world of modern construction, "Precast Concrete Lifting Eyes" play a crucial role in ensuring safety and efficiency. Expert Charles Whitmore states, "Lifting eyes are essential for the reliable handling of precast elements." The structural integrity of concrete pieces depends significantly on these lifting systems. Their design must address various factors, such as load capacities and environmental conditions.

Construction projects can become chaotic. Sometimes, the right lifting eye may not be available on-site. This can lead to delays and increased costs. Each precast piece is unique; thus, the lifting eyes must align perfectly with the intended use. Unsurprisingly, poor planning can create challenges. This underscores the need for meticulous attention to detail in selecting and using lifting eyes.

In recent years, the industry has seen innovations in design and materials. However, challenges remain. Some lifting eyes may not withstand harsh conditions, leading to safety risks. It’s vital for engineers to regularly reassess these components. Mistakes can be costly. Focusing on quality and adherence to standards is a must for improving safety and efficiency on construction sites.

Understanding precast concrete lifting eyes is essential in the construction industry. These lifting eyes are crucial for safely handling and positioning precast components. According to recent industry reports, improper use of lifting eyes can lead to significant safety hazards. Fractured components or accidents can incur costs upwards of thousands in repairs and delays.

Choosing the right lifting eyes depends on the project specifications. The concrete's weight and dimensions should dictate the type and quantity of lifting eyes used. For instance, a standard lifting eye can typically support a weight range of 5 to 15 tons. However, applying too much weight or using insufficient lifting points can lead to failure.

Tips: Always verify the lifting eye capacity before use. Inspect the eyes for damage or wear. A small crack can lead to disaster.

In construction, standard conventions must be followed. Workers need training on how to align and lift components correctly. Misalignment during lifting can cause the piece to swing or drop unexpectedly. This issue is often overlooked during project planning. Regular safety assessments can help identify potential risks early.

Tips: Conduct frequent training sessions. Encourage feedback to avoid reliving past mistakes. Engaging team members in safety discussions can foster a safer work environment.

| Lifting Eye Type | Weight Capacity (lbs) | Material | Installation Method | Typical Use Case |

|---|---|---|---|---|

| Standard Lifting Eye | 5000 | Steel | Welded | Wall Panels |

| Heavy-Duty Lifting Eye | 10000 | Cast Iron | Bolt-On | Bridge Elements |

| Adjustable Lifting Eye | 7500 | Aluminum | Welded | Custom Shapes |

| Lightweight Lifting Eye | 3000 | Composite | Embedded | Precast Walls |

In construction, precast concrete lifting eyes play a crucial role in transport and installation. They are integral for moving heavy concrete elements safely. Various types are available, including bolts, looped wires, and embedded fittings. Each type serves specific applications, catering to diverse project needs.

For instance, bolted lifting eyes are commonly used for wall panels. They provide a secure attachment for cranes, ensuring stability during lifting. Lifting loops, often embedded in beams, allow for efficient hoisting and reduce loading time. Understanding these variations helps contractors select the right method for their projects.

Tips: Always inspect lifting eyes before use. Look for signs of wear or damage. Proper maintenance can prevent accidents during lifting. Additionally, ensure that the load limits of each lifting type are clearly understood. Safety should always come first.

Considering that improper use can lead to significant costs, contractors need to reflect on their choices. Selecting the wrong type of lifting eye could compromise structural integrity. Regular training for construction crews on equipment use is also essential to minimize risks. The right knowledge can enhance both safety and efficiency in the field.

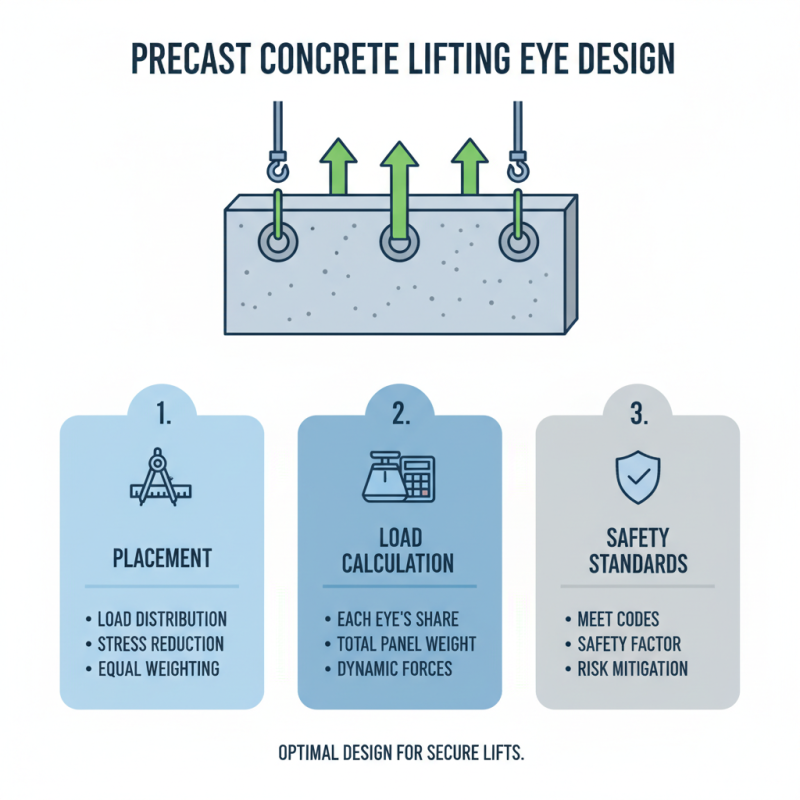

When designing precast concrete lifting eyes, several factors come into play. First, the placement must ensure that the lifting eyes can handle the load without risk. Proper placement reduces stress and distributes weight evenly across the structure. It’s crucial to calculate the load that each eye will bear and ensure it meets safety standards.

Tips: Always use quality materials. This ensures that lifting eyes perform well under pressure. Regular checks during fabrication can catch issues early. Monitor the connection between the lifting eyes and the concrete. A weak bond can lead to failure.

Visibility of the lifting eyes is also important. They should not be obscured by other components of the structure. This makes them easier to access during lifting operations. Balancing practicality with aesthetics is often challenging. Designers should consider various scenarios to ensure they select the best configurations. Imprecise designs can lead to complications during lifting, highlighting the importance of thorough planning.

When installing precast concrete lifting eyes, attention to detail is crucial. Proper installation ensures safety and efficiency on the construction site. Check the lifting eyes for any visible damage before installation. This simple step can prevent future issues during lifting.

It’s important to follow the manufacturer’s recommendations closely. Misalignment can lead to structural weakness. A level surface is vital. Make sure the lifting eyes are installed at the correct angle. Incorrect installation may compromise the entire lifting operation.

Tips: Always conduct a load test before the actual lift. This helps identify any potential failure points. Use a qualified engineer to review your installation plan. Their expertise can save time and reduce risks. Documenting the installation process can also provide valuable insights for future projects.

When lifting precast concrete elements, safety is paramount. Proper adherence to safety standards and regulations can prevent accidents. Each lifting procedure requires careful planning and execution. This includes ensuring all equipment is certified and inspected regularly. Operators should be well-trained, familiar with the handling of heavy loads.

The right lifting eyes must be selected based on the specific precast element. Every project might present unique challenges that need tailored solutions. For example, weather conditions can significantly affect lifting procedures. Concrete can absorb moisture, making it slippery. When it rains, workers might bypass safety checks, which can lead to serious incidents.

Despite available resources, some construction teams overlook safety protocols. They may underestimate risks associated with lifting. It's crucial to involve all team members in discussions about safety measures. Everyone should feel responsible, from laborers to project managers. By fostering an environment of awareness, the likelihood of accidents can be minimized. This ongoing reflection on safety practices is vital for improving outcomes in precast concrete construction.

This chart represents the importance levels of key factors affecting the safety and efficiency of precast concrete lifting eyes in construction. The data reflects industry standards and best practices for ensuring compliance and operational safety.