0102030405

Adaptor For Precast Concrete Shuttering Magnet

The Adaptor For Precast Concrete Shuttering Magnet is a magnetic adapter for precast concrete molds, which plays an important role in the manufacturing of precast concrete elements with connecting rebar and complex geometries. The use of this adapter increases productivity while maintaining product quality and cost effectiveness.

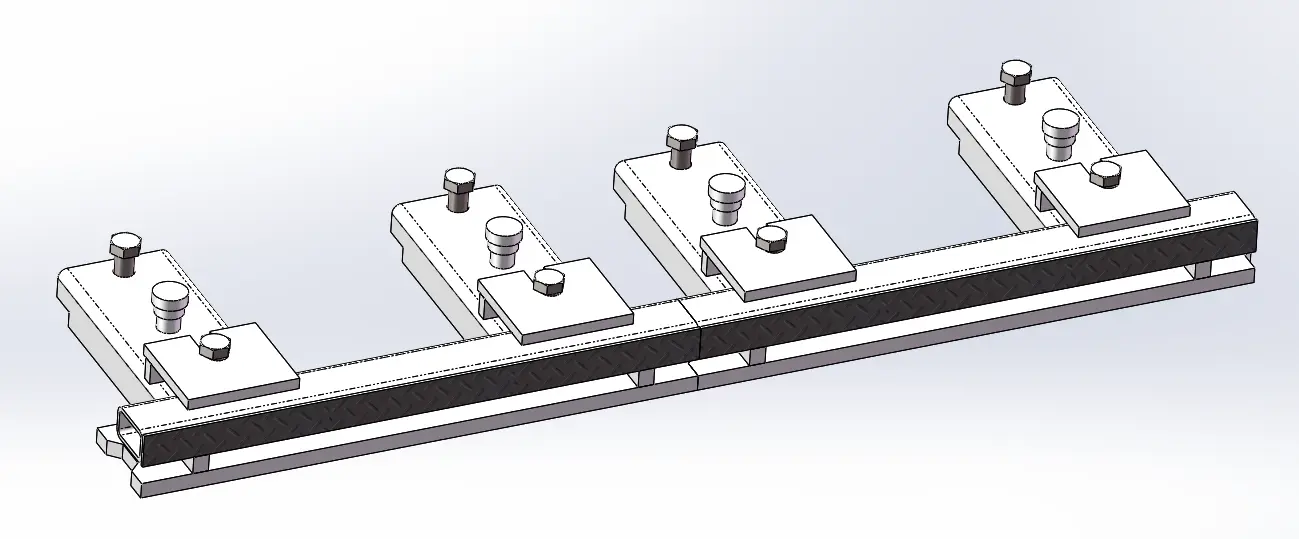

Working principle diagram of Adaptor For Precast Concrete Shuttering Magnet

Role:

- Used for joining reinforcing bars, especially when automated solutions are required to cope with increasing production demands.

- Used in conjunction with mold systems to adapt to different building standards or structural requirements.

- Can be combined with various additional modules, such as C-rails for fixed formwork and fixed or flexible chamber modules for continuous reinforcement.

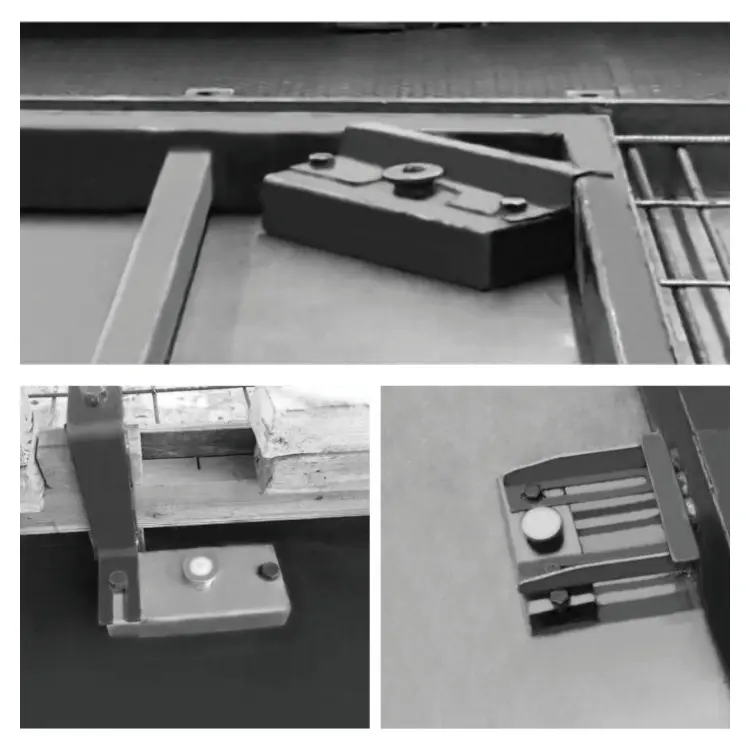

How Precast Concrete Formwork Magnet Adapters Work

Usage:

- When precast concrete elements require the attachment of reinforcing steel or other complex geometries.

- In automated or robot-assisted precast concrete production processes, especially in precast production using mold robots.

Features and Benefits:

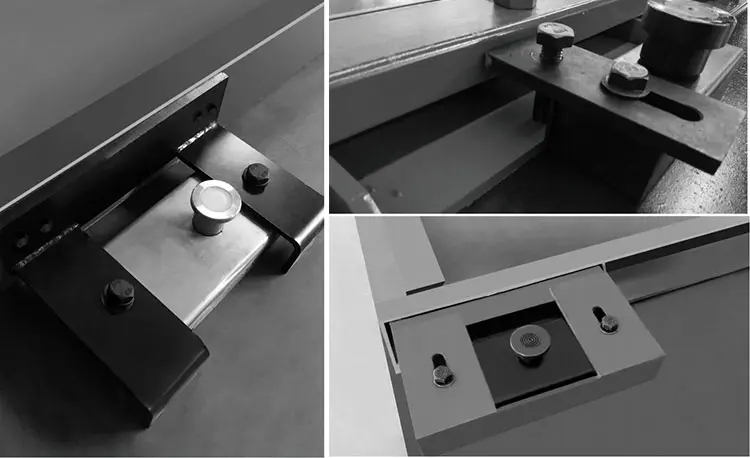

- Provides a flexible and adjustable solution to accommodate complex element geometries.

- It is possible to reduce the cost of the material required to connect the reinforcement, for example by using wire rope ring inserts to save on the cost of a complete wire rope ring box.

- The use of magnetic adapters simplifies the mold assembly process as they can be easily attached to the mold without additional measurements.

- The magnetic height of the adapters can be flexibly and infinitely adjusted, providing a simple but reliable method of solving problems associated with complex element geometries.

- They can be used in conjunction with robot-compatible standard mold elements and special mold elements for highly automated production processes.

By using these magnetic adapters, manufacturers are able to achieve more efficient and cost-effective production while complying with building standards and structural requirements.

Use cases for magnet adapters for precast concrete formwork

The use of magnetic precast concrete fixtures (Shuttering Magnets) offers a number of potential economic benefits in addition to increased construction efficiency:

1. cost savings: the use of magnetic fixtures reduces labor costs by reducing the need for additional manpower and allowing for quick, single-person installations compared to traditional form-fixing methods.

2. Improved safety: Improved safety on the construction site by reducing the risk of tripping caused by the use of other fixing tools such as clamps and welding equipment.

3. Reducing material waste: Reducing the use of construction materials through precise formwork fixing avoids unnecessary waste and further saves costs.

4. Enhancement of project quality: the magnetic fixture can provide a stable and strong fixing force to ensure the accuracy and stability of the formwork during the concrete pouring process, thus improving the quality of the final product.

5. shorten construction cycle: due to the convenience of installation and disassembly, it can speed up the construction progress, shorten the completion time of the project and put it into use earlier, thus bringing economic benefits.

6. Environmentally friendly: Reducing noise and dust at the construction site reduces the impact on the surrounding environment, which is in line with the requirements of green building and sustainable development.

7. Improvement of mold use efficiency: Since prefabricated components can be quickly demolded under factory conditions, it improves the turnover rate of molds and reduces the investment cost of molds.

8. Wide adaptability: Magnetic fixtures can be adapted to the production of concrete elements of different shapes and sizes, increasing the flexibility of the production line and enabling it to meet diversified construction needs.

Together, these economic benefits provide a cost-effective construction solution for building projects using precast concrete magnetic fixtures.