0102030405

2000 lbs Carbon Steel Precast Concrete Shuttering Magnet

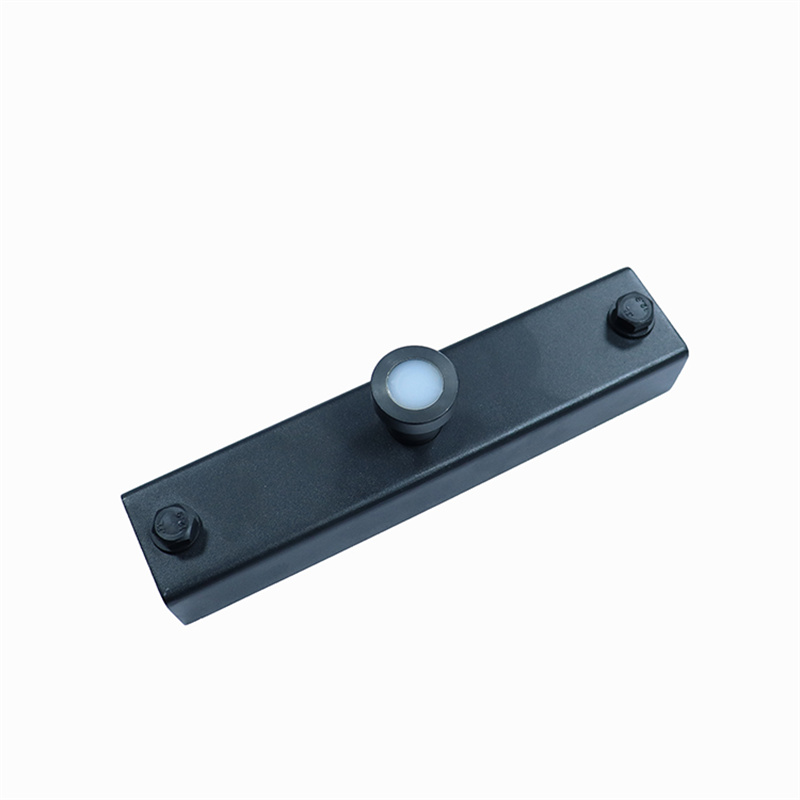

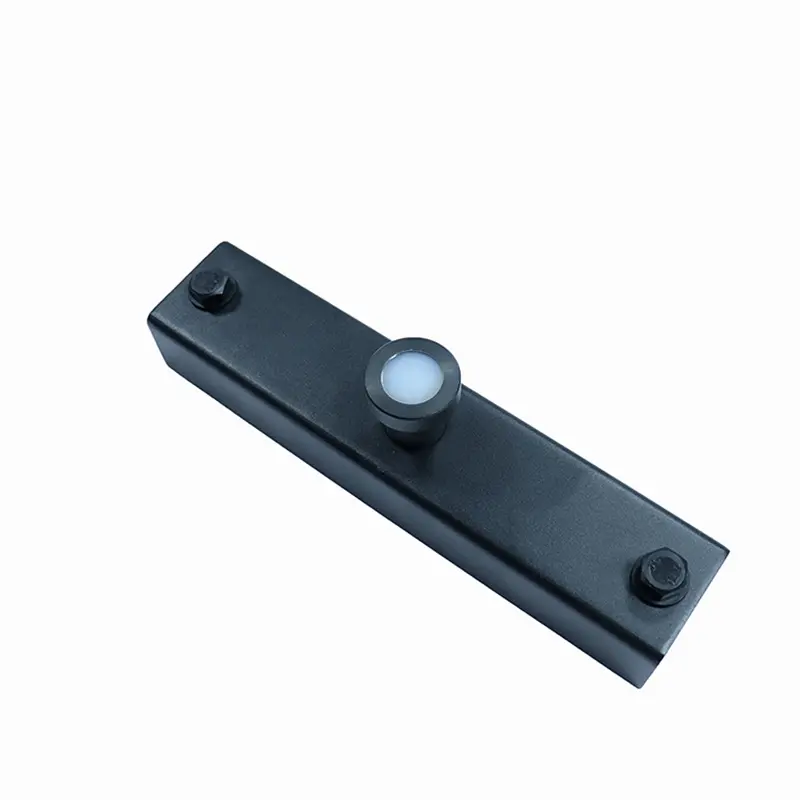

The precast magnets with a pulling force of 900 kg (2000 lb) are relatively small in the family of magnetic catches. The reason for this is the small size of the magnet assembly inside the box, which generates a vertical magnetic force of 900 kg (2000 lb). The magnet assembly consists of eight magnets made of neodymium-iron-boron material. The outer layer of the magnets is galvanized and fitted with a protective sleeve. The magnets are clearly arranged in groups of 4, divided into 2 groups, clamped on both sides with steel plates and interlocked with screws to form a magnetic field. With a magnetic force of 900 kg (2000 lb), the locking magnets are ideal for the production of wall panels with a thickness of 60-90 mm. They are activated by pressing the button by hand or foot or by lightly tapping the button with a wooden or rubber mallet. To release the button, simply pull it upwards with a steel rod. It can be used on its own or screwed on both sides in conjunction with an adapter.

Product parameters

|

Name |

precast concrete magnet/shuttering magnet |

|

Item |

QCM-900 |

|

Pull force |

≥2000 lbs(900kg) |

|

Net weight |

2.7kg |

|

Size |

280x60x40mm |

|

Material |

N grade neodymium+steel shell+iron sheet |

|

Load time |

14-20 days, the fastest time 5-7days |

|

Package |

anti-magnet, carton, iron box |

|

Certificate |

ISO9001, ROHs, CE, TS16949, etc |

|

Application |

Construction build, Industrial magnet |

|

Payment Type |

Wire transfer, western union, paypal |

|

Transportation |

By sea,by air, by express |

To prevent the magnets from sticking to each other during transportation, the buttons are made of a magnetic imitation material. Fatigue durability simulation tests with over 100,000 cycles prevent any deformation or failure, so you can use them again and again. With a suction force of 900 kg, the locking magnet weighs just 2.7 kg, offering flexibility that cannot be achieved with larger prefabricated magnets. Skilled workers can use it to fasten concrete frames in a very short time, which significantly increases efficiency. The flexibility and lightness of the magnet gives it a strong position in the market.

We have worked hard to improve the yield by introducing fully automatic laser cutting machines from Europe, improving precision guide rails, bending machines and so on. We have mastered almost all the processes and equipment for the production of stamped magnets, strengthened internal quality and process control, quality control and material purchasing control, and our internal control is better and stricter than that of our competitors.

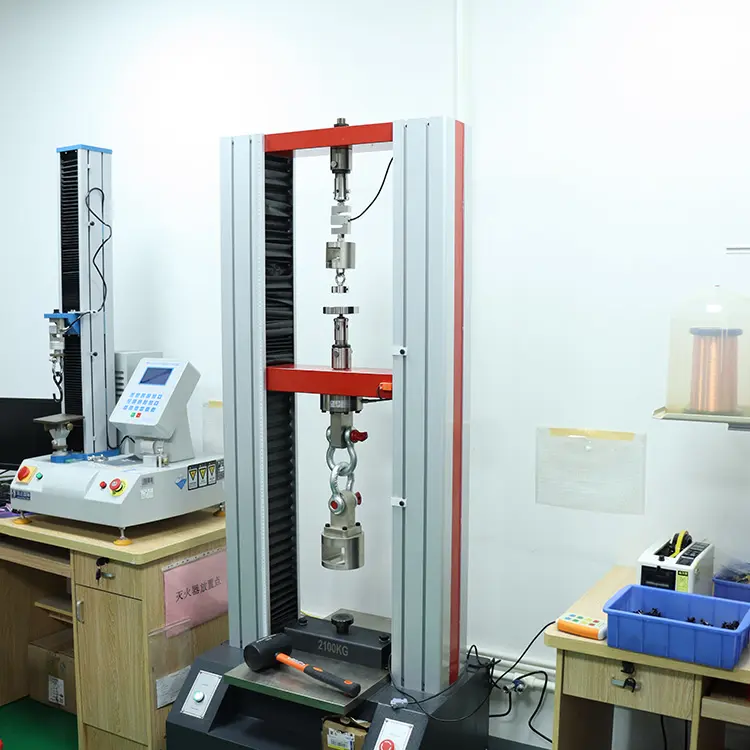

Qianci magnet shutting magnet box pull force test equipment

We have a large selection of models, large quantities and low prices, with a magnetic force of 450 kg to 3100 kg. We offer you a one-stop solution. From prefabricated magnets to template magnets, insert magnets, magnetic bevels and so on. We also accept customized production and personalized service in terms of magnetic force, product specification, appearance design, surface treatment of housing and so on.

Packaging and Shipping Methods

1. Basic Packaging:

- The shutter magnet is packed in a double corrugated cardboard box and secured with packing tape.

- Inside the carton, use high-quality foam board to insulate the magnets to prevent scratches and damage.

2. Sea Freight Packaging Options:

- 1.1 Pallet packing: a common packing method for sea transportation.

- 1.2 Wooden crates: more formal appearance, cost $35/carton more than pallets.

3. Notes for air transport:

- Magnetic items are considered sensitive during air transportation and may affect aircraft safety.

- Anti-magnetic treatment is required to ensure magnetic compliance with aviation standards.

- When packing, please place a thick iron sheet or iron box between the foam and the carton to ensure anti-magnetic treatment.

4. Air freight forwarding requirements:

- Magnetic testing is required when using FedEx, DHL, UPS, TNT and other air freight and express services.

- If magnetic shipments are mixed with non-magnetic shipments, magnetic testing of all shipments is required.

5. Magnetic inspection report:

- Magnetic inspection reports are unique and not reusable.

- With the exception of FedEx and DHL, the other logistics channels accept annual magnetic inspection reports.

6. Railway transportation:

- The packaging standards for rail transportation are the same as for air transportation.

The packaging and shipping of shutter magnets requires special attention to the safe handling of magnetic items and compliance with shipping standards. There are two packaging options for sea transportation: Pallets and wooden crates, while air transportation requires additional anti-magnetic treatment and magnetic inspection. Strict packaging and inspection standards should be followed for all shipments of magnetic items to ensure safety and compliance.