0102030405

1000 lbs steel precast concrete shuttering magnet

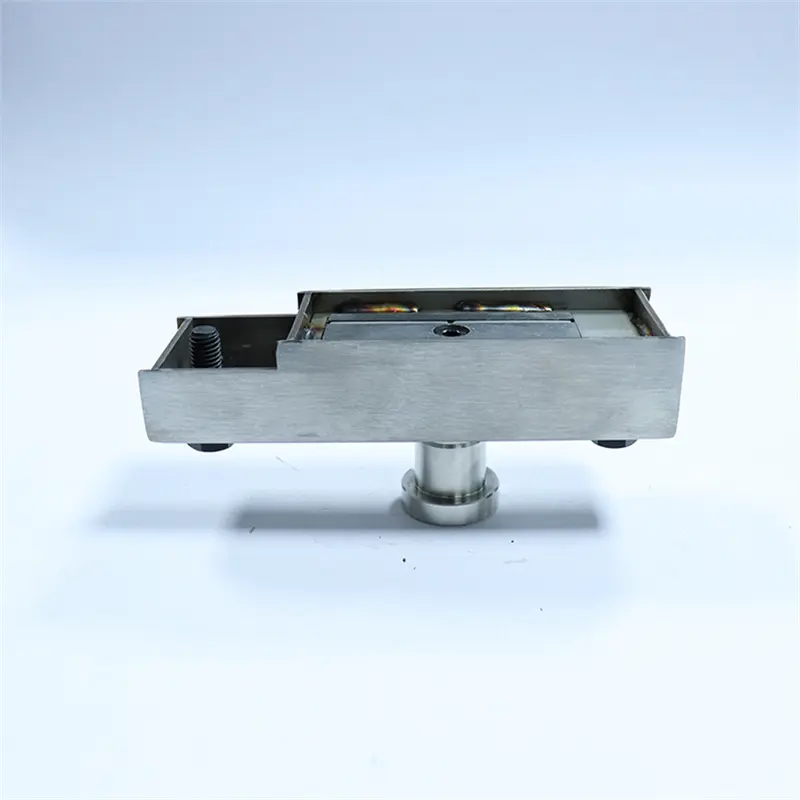

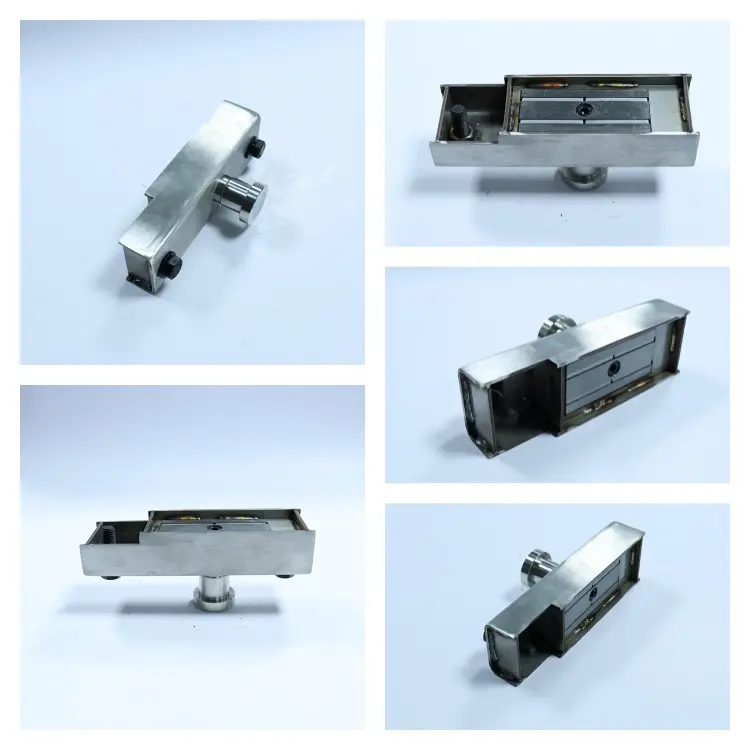

The 450kg steel prestressed concrete formwork magnet is specially designed for formwork fixing in precast concrete industry. Its main function is to firmly fix the formwork to any iron workpiece by strong magnetic force, thus ensuring the stability and safety of the formwork during construction.

The magnet has the following advantages

1. Strong adsorption force: It is made of strong NdFeB magnets and steel plates, which can generate extremely strong attraction force, and its pulling force ranges from 450kg to 3000kg.

2. Easy operation: There is an on/off switch on the top to connect or detach the template, making the whole operation process simple and quick.

3. High efficiency: Compared with the traditional bolt fixing method, magnets can be quickly disassembled and reassembled, which reduces labor costs and reduces the waste of steel platforms.

4. Strong protection: NdFeB magnets are wrapped in high-quality iron shells to effectively prevent damage to the magnets and have anti-rust treatment.

Compared with other series of formwork magnets, 450kg steel formwork magnets for prestressed concrete have the following differences:

1. Suction size: Different models of formwork magnets have different suction forces. For example, 1800kg and 2100kg magnets are suitable for large steel prestressed concrete platforms.

2. Materials and design: Some models can use stainless steel or higher quality materials to improve magnetic force and corrosion resistance.

3. Application range: Different formwork magnets can be suitable for different shape and size requirements to meet the needs of different architectural designs.

450kg steel formwork magnets for prestressed concrete are widely used in the precast concrete industry due to their strong adsorption force, easy handling and efficient performance. There are certain differences from other series of formwork magnets in terms of suction force, material and design, and application range.

What is the specific working principle of the 450kg steel prestressed concrete formwork magnet?

The special working principle of 450kg steel prestressed concrete formwork magnet is achieved by the strong magnetic field it generates. Magnets for precast concrete parts can hold both ends of the steel rods firmly in the formwork, so that no sparks or flames are generated during concreting, and there is no danger to people or surrounding buildings.

Compared with the traditional bolt fastening method, using 450kg steel prestressed concrete formwork magnets can save a lot of labor costs and reduce the waste of steel platforms.

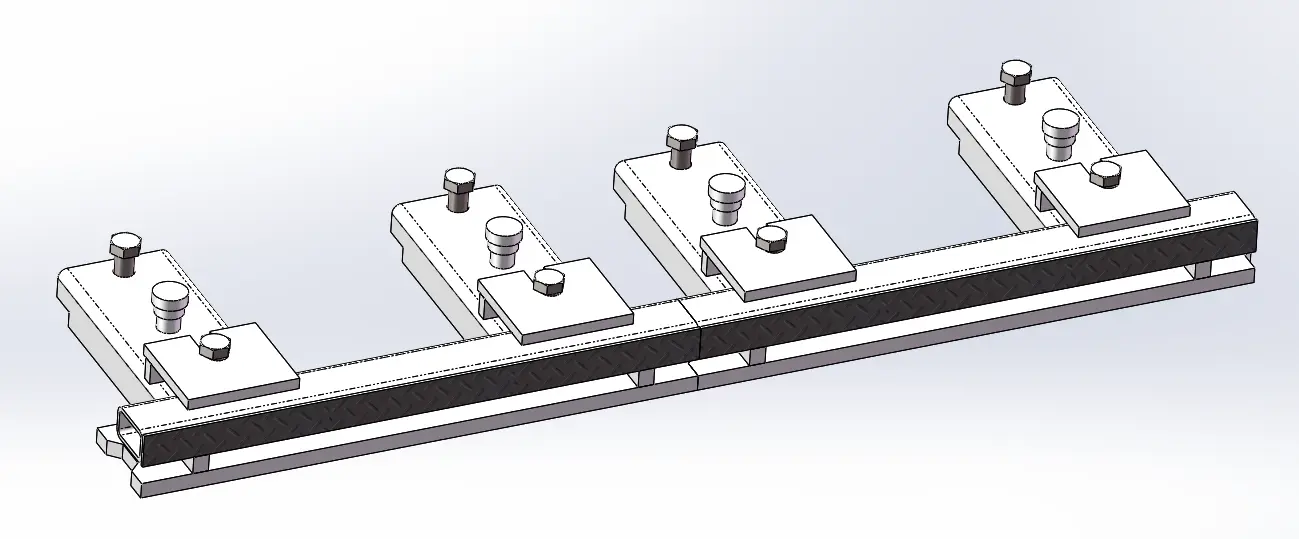

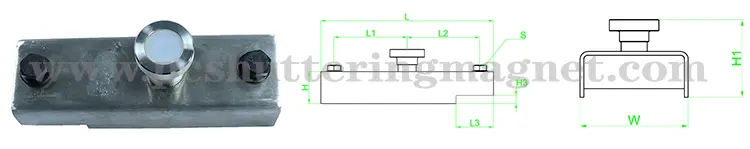

QCM-450 steel stepping shuttering magnet fixes the template with the help of the adapter

The traditional bolt fastening method requires drilling, tapping and screwing. The tools are not coordinated, which is a significant waste of labor time. On average, it takes about two hours to fasten a column. The magnet fastening method uses magnetic expertise to design the most reasonable magnet module, which not only meets production requirements but also does not waste magnetic resources, thus saving costs for customers. In particular, the reinforcement speed of the magnet fastening method is about 5 times that of the traditional reinforcement method, saving 4/5 of the manpower. This means that with the same amount of labor, the use of magnets can reduce labor costs by 4/5.

In addition, traditional fastening methods mainly rely on metal parts such as bolts for fastening. These metal parts may be worn or damaged due to repeated disassembly and assembly during use, increasing material waste. With the magnetic fixing method, the template can be firmly fixed on the steel workbench thanks to the special magnetic circuit design and extremely strong suction force, reducing the dependence on and use of metal parts and thus reducing material waste.

|

|||||||||

|

Model |

L(mm) |

L1(mm) |

L2(mm) |

L3(mm) |

W(mm) |

H(mm) |

H3(mm) |

S |

Breakaway |

|

QCM450B |

190 |

77 | 77 | 50 |

60 |

40 |

10 |

M12*40 |

450 |

|

QCM600B |

200 |

72.5 |

95.5 |

42 |

60 |

43 |

10 |

M12*40 |

600 |

|

QCM1000B |

200 |

65 |

100 |

50 |

95 |

60 |

10 |

M12*40 |

1000 |

|

QCM1350B |

320 |

113 |

161 |

47 |

90 |

60 |

10 |

M16*60 |

1350 |

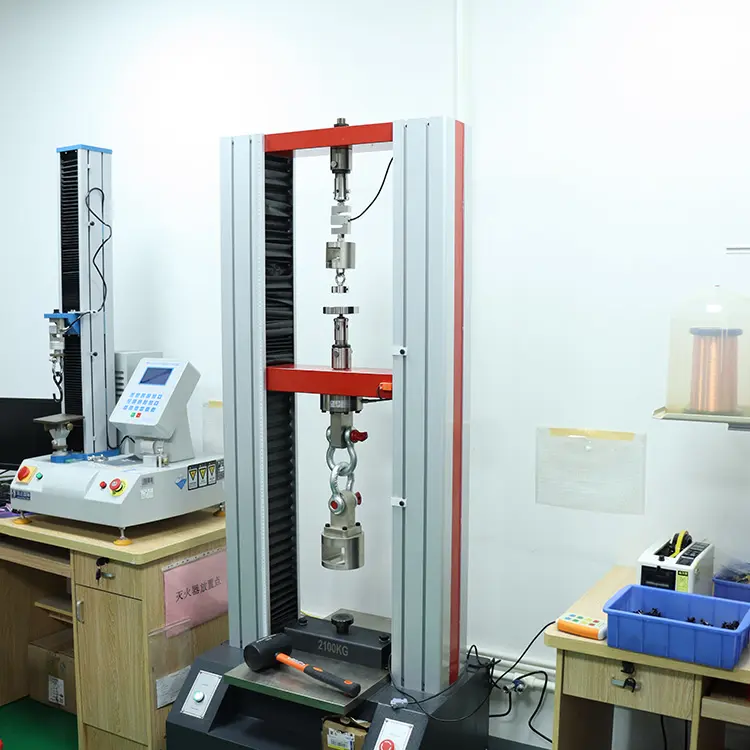

QCM magnet shutting magnet box pull force test equipment